20/10/2025 – This is how the color of the internet is made: the keys behind

Optical fiber in the era of connectivity and AI

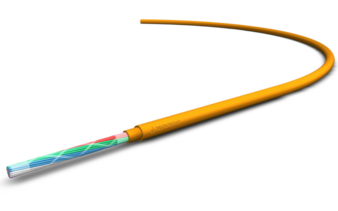

Without telecommunications cables, the digital economy as we know it would not exist. They are the arteries through which the information we use every moment flows: from a simple WhatsApp message to streaming a movie or training an artificial intelligence model. In 2025, their role is more crucial than ever, and among them, there is one indisputable protagonist: optical fiber.

This technology lies at the heart of the major advancements transforming the world: the rollout of 5G and the future 6G, the automation of homes and cities, and the connectivity required by the data centers powering AI. The global optical fiber market closed last year at $8.7 billion and is expected to approach $15 billion by 2033, growing at an annual rate of 6.2%, according to Business Research. In other words, fiber is not only everywhere – it’s presence will continue to expand over the next decade.

But the story of optical fiber isn’t just about cables. Behind every installation there is innovation, precision, and a healthy dose of materials science. For example, the coloring of the cables may go unnoticed by the end user, yet it is essential for the entire network to function properly.

Colors make the difference in optical fiber

This is where Delta Tecnic comes into play, a company specialized in the formulation and production of masterbatches: concentrated pigments and additives that are mixed with plastics to give them color and specific properties. For Delta Tecnic, optical fiber is not just another niche—it accounts for more than 80% of its telecommunications revenue.

Why is color so important in cables? Because each shade serves an identification purpose, allowing installers and technicians to know exactly what each component is in a complex cabling system. Precision is key: if the color concentration or opacity is off, identification can fail, leading to wasted time, installation errors, and additional costs.

Delta Tecnic’s masterbatches are designed to ensure that cables maintain their concentricity—that is, that each layer remains perfectly centered—something essential to prevent data transmission losses. A cable that does not meet this requirement can degrade the flow of information and affect the entire system.

Prepared for all conditions

Beyond the interior, there is the exterior. Optical fiber cables installed outdoors need to withstand rain, sun, cold, and heat without losing their properties. That’s why Delta Tecnic develops high-performance masterbatches for outer sheaths, capable of maintaining both color and mechanical strength over the years.

And it’s not just the weather that threatens these cables: rodents and termites do too. As incredible as it may seem, their bites can cause service interruptions across entire areas. To prevent this, the company offers additives that act as non-toxic repellents, based on odors and tastes unpleasant to these animals. This way, the infrastructure is protected without harming the ecosystem.

The era of smaller cables

One of the major current challenges in the industry is miniaturization. The smaller the cables, the less space they occupy in installation ducts, which reduces costs for operators. But making cables smaller also means that the walls of the tubes housing the fibers are thinner… and that makes coloring more complicated.

If the tube is not opaque enough, the color of the inner fibers shows through and masks the tube’s true hue. This causes confusion in identification, especially with similar colors such as red/pink or yellow/orange.

Delta Tecnic’s next-generation masterbatches solve this problem thanks to their high opacifying power. They allow even the thinnest tubes to retain their original color and be easily identifiable for installers. In addition, the company has managed to reduce masterbatch dosing during extrusion by more than 25%, meaning less material consumption without compromising quality.

Thus, the close collaboration between cable manufacturers and masterbatch suppliers is what is making this new generation of solutions possible. Thanks to these advances, it is now possible to produce optical fiber cables that are thinner, more efficient, and more reliable, able to meet the demands of a growing market. And this doesn’t stop here: as connectivity demand continues to rise, innovation in materials will remain a key driver for faster, more cost-effective, and sustainable infrastructure deployment.

Cable & Wire Fair 2025, booth 3/R1-1

Delta Tecnic S.A.

C/ Rec Molí de les Planes s/n

Pol. Ind. Molí de les Planes

08470 Sant Celoni, Barcelona, Spain

Tel.: +34 93 8674284

deltatec@deltatecnic.com

www.deltatecnic.com