28/06/2021 – Self-scoring system for eco-designed products

“Lubriscore”

In order to offer customers better readability and maximum transparency of its products, Condat introduced the "Lubriscore" in 2020. The Lubriscore is a Condat self-assessment system that evaluates product properties based on life cycle criteria: Raw materials and design / Production / Transport / Use / End of life.

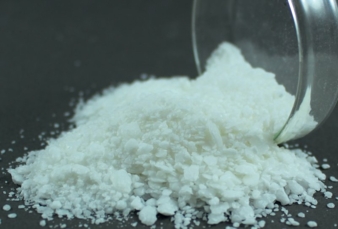

The Lubriscore rating is available for a wide range of Condat lubricants, including wire drawing soaps, metalworking fluids, cold heading oils, hydraulic oils, die lubricants, cooling lubricants, hardening/quenching fluids and maintenance lubricants. © Condat