28/06/2021 – Self-scoring system for eco-designed products

“Lubriscore”

In order to offer customers better readability and maximum transparency of its products, Condat introduced the "Lubriscore" in 2020. The Lubriscore is a Condat self-assessment system that evaluates product properties based on life cycle criteria: Raw materials and design / Production / Transport / Use / End of life.

This rating includes impacts on people and the environment and takes into consideration the state of knowledge at the time of the assessment and changes to regulations. A bonus is applied in case of compliance with a label or certification; as for example for an “Ecolabel” certified product.

Based on a points system and on the answers given to about twenty questions, the “Lubriscore” grants, or not, the product with an associated number of stars. The more eco-designed a lubricant is, the higher the number of stars it gets, the ratings range from 1 to 3 stars. By choosing a product with at least one star, you benefit from an eco-designed alternative!

The Lubriscore rating is available for a wide range of Condat lubricants, including wire drawing soaps, metalworking fluids, cold heading oils, hydraulic oils, die lubricants, cooling lubricants, hardening/quenching fluids and maintenance lubricants.

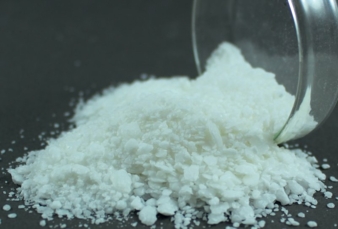

An eco-designed range for wire drawing soaps

Condat has also been keen on offering safer lubricants for the wire drawing industry. As the first supplier of lubricants 20 years ago, boron free pre-coatings and calcium and sodium soaps, or even lubricants designed to increase productivity and reduce energy and consumption costs, the company has kept a crucial competitive edge in supplying lubricants providing responsible performance.

Proof of this is that Condat's wire drawing range now includes around 40 products that have been classified as environmentally friendly by the "Lubriscore" programme. It is the result of a long-term strategy aiming at improving a product’s footprint.

Condat eco-designed lubricants are characterised by several of the following benefits. Careful attention is paid to the key raw materials used in product formulas. In fact, they are usually supplied in large quantities to limit packaging waste and thus reduce waste volumes. Moreover, in order to protect customers and the environment, Condat’s policy is to eliminate CMR raw materials in formulas, and to reduce as much as possible the use of hazardous components. For example, highly efficient soaps and surface treatments have been developed without Borax and TiO2. To provide the highest performance and productivity, formulation of the product is tailored to each customer’s application to ensure reduction of dust, die wear, lubricant consumption.

Finally, their eco-designed range is also characterised by a reduced production footprint, with lower energy required to manufacture the products (manufacturing temperature and time).

Condat

Tel.: +33 4 78073711