24/09/2021 – Niehoff and NENA at Interwire 2021

Industry 4.0 concept with a “BMV 16” braider

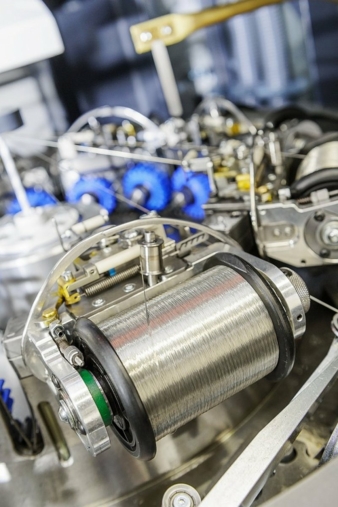

Maschinenfabrik Niehoff and its subsidiary Niehoff Endex North America, Inc. (NENA) will have as main displays on booth the rod breakdown machine type “MSM 83” with individual capstans in a small footprint and as second main display and a “BMV 16.S” braiding machine with “WTC” wire tension control for application in medical technology.

In addition, the offerings of the After Sales Service and the Niehoff Original+ components will be showcased at the booth as well. By means of a video, visitors will get an insight into the retrofit of the gear box and the gear overhaul of an “MMH” multiwire drawing machine with tens of thousands of operating hours. The visitors will also learn how they can use Niehoff’s digitization concept. With Niehoff’s Industry 4.0 offer, the Niehoff Digital Assistant+, machine, production and process data can be recorded. Thus, continuous process monitoring and machine condition analysis are possible. One example is the operation of the “BMV 16.S” braider. It is planned to show a video of the Niehoff Digital Assistant+ with machines and condition monitoring.

The compact rod breakdown machine type “MSM 83” with electronic controls is designed to draw rod wire made of copper and copper alloys to a finished diameter range of 1.38mm (0.054”) to 4.56mm (0.179”) equipped with 11 drafts. The MSM 83 can operate at speeds up to 38m/s (7,480fpm) and is available in 11, 13 and 15 drafts. As the drawing capstans are placed on two levels, the MSM 83 is short to fit in tight spaces.

The vertical lever arm rotary braiding machine type “BMV 16.S” on display is foreseen for the production of medical technology products. Via the WTC (Wire Tension Control) system, the braider regulates the braiding wire tension of the braiding bobbins, from full to empty condition. Consequently, all braiding wires are applied under uniform tension to the product to be braided. The braider keeps also the braiding coverage ratio of the product to be braided constantly at the pre-set value. As only as much braiding wire as necessary is applied, up to 15% braiding material or even more is saved in comparison with conventional braiding machines. Furthermore, the braider can automatically accelerate the bobbin rotational speed from 175rpm to a maximum value of 200rpm while reducing the frequency of the lubrication intervals. This results in an increasing braiding output by 10% and braids which are less contaminated with oil.

Maschinenfabrik Niehoff GmbH+Co. KG

Interwire 2021, booth 841

Tel.: +49 9122 977-0

www.niehoff.de

Niehoff Endex North America Inc.

Tel.: +1 856 467-4884

www.niehoffendex.com