20/03/2025 – Spools filled to perfection and substantial cost savings

Highest bunching quality

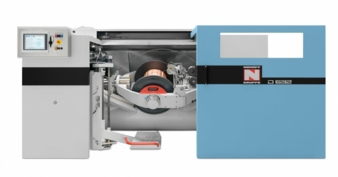

Maschinenfabrik Niehoff will be presenting at the “wire Eurasia” a “D 632” type double twist bunching machine, and their After Sales Service offers.

The “D 632” type double twist bunching machine features high productivity and delivers high-quality products on perfectly filled spools. Those who use the “D 632” benefit from a number of advantages. The single-bow design in combination with the energy-saving Eco-Bow used here saves considerable amounts of energy. This results in significant energy cost savings compared to conventional bunching machines.

Further features of the machines are the electric lay-length adjustment (changing lay-length without changing gears) and the constant tension control of the strands from empty to full bobbin. As the “D 632” produces strands with very tight tolerances, only the minimum required copper cross-section is generated. Consequently, this leads to major savings in material and operating costs.

The variable and controlled wire tension – independent of the spool filling – together with the integrated opto-electronic “NBAT” (Niehoff Bunching Automatic Traverse) system allow the spools to be filled with a perfect winding pattern. It is thus possible to pay-off the strands tangle-free at extremely high pay-off speeds. Thanks to the machine´s precise mode of operation and the automatic “NBAT” system, one operator can simultaneously supervise the operation of several machines. The result is substantial savings in labour costs.

The bunching data can be documented so that the user of a “D 632” can provide his customers with written quality documentation. Important production parameters such as winding tension, lay length and the number of twists can be logged. The condition monitoring enables users to monitor machine and process data online. The “D 632” buncher is ideal for processing fine wires made of copper alloys such as CuSn0.3 into strands for automotive cables. Thanks to the patented Stretch Forming and Straightening Technology, the “D 632” avoids the crowning and spiraling effect typical of wires made from certain copper alloys.

Technical data: D 632

max. production speed: 300 m/min

strand cross section*: 0.09 … 6.00 mm²

lay length (steplessly variable): 6 … 100 mm

max. number of twists: 7000 twists/min

*Cu soft

At the fair stand, visitors can also experience the wide range of “Niehoff LifeCycle+” services and how they can benefit from “myNiehoff”. These offers contribute to further increasing the productivity and production reliability of Niehoff machines and to sustainably reducing operating costs.

wire Eurasia 2025, hall 8 booth 817-G

Maschinenfabrik Niehoff GmbH+Co. KG

Walter-Niehoff-Strasse 2

91126 Schwabach/Germany

Contact person is Norbert Meyer

Tel. +49 9122 977-0

info@niehoff.de

www.niehoff.de