10/10/2024 – Cold forging

Tool strength has never been more compact

High tool loads are a challenge in cold forging processes of all sizes. While previously limited to a minimum outer diameter of 80mm, compact Strecon stripwound containers now offer optimized prestressing in installation spaces as small as 36mm in outer diameter.

Cold forging is a very resource efficient production technology. Compared to hot forging, parts with higher quality are produced resulting in less aftermachining, a better overall material usage, and reduced energy consumption. However, the material deformation at room temperature is only possible with high forces and, consequently, high tool loads. Due to a demand for more complicated part geometries made of high-strength materials there is a trend of increasing tool loads within cold forging processes. This represents a challenge, as high-loaded tools often experience premature fatigue failure, which leads to a bad economic efficiency. Therefore, there is a need for stronger tool systems.

High prestressing is an efficient way to increase tool strength by reducing tensile stresses that are causing fatigue cracks. Strecon stripwound containers have been used for this exact purpose for many years with great success. They are produced by winding a thin steel strip around a steel or carbide core. Thanks to an increased material strength of the strip material and a better distribution of stresses in the container, stripwound containers offer a 50% – 100% higher tool strength compared to conventional single or double ring reinforcement systems.

High tool loads are not limited to big tools or big parts. While the absolute force necessary to forge a part is reduced with smaller sizes, the pressure on the tool remains on the same level, since it is calculated as the force per area. For this reason, Strecon has developed a compact stripwound container designed specifically for high prestressing in limited installation spaces. Until recently, the minimum outer diameter of stripwound containers was 80mm, but with the new compact design it has been reduced to 36mm.

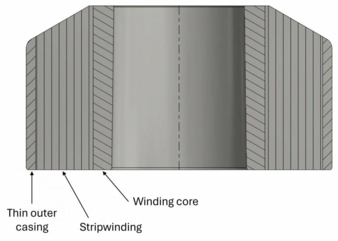

The compact containers are generally built similarly to normal stripwound containers: The winding core is surrounded by stripwinding, and the container is completed by a very thin outer casing, which is the main design feature for the compact containers. That way, most reinforcement space is left for the stripwinding, which creates the technological advantage of high reinforcement strength.

The initial compact containers have been designed for the forging of customer parts with a diameter of 6 mm. This shows that new application fields for Strecon containers are now available, for example on horizontal cold-forming machines designed for wire material with small diameters. By using the compact reinforcement tools in these applications, it is now possible to forge quality parts at even higher tool loads while obtaining a stable and economic process performance and tool life.

The author of the article is Martin Killmann.

Strecon A/S

Stødagervej 5

6400 Sønderborg/Denmark

Contact person is Martin Killmann

Tel.: +45 74 487788

info@strecon.com

www.strecon.com