05/11/2024 – Specialised machine manufacturer impresses with customised solutions

Winding technology – flexible like never before

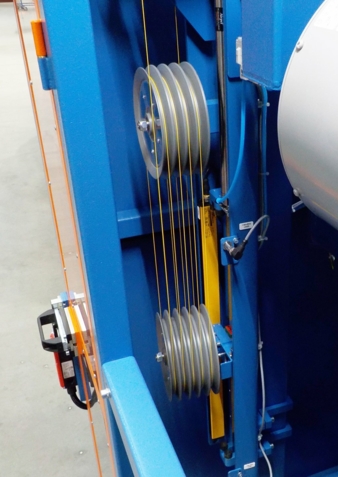

Flexibility is desired in all areas of cable production - but realising this often is a major challenge. The topic of winding also falls into this category. Kurre Systems is producing a product family of fully automatic double winders with improved parameters and features for fast, reliable and, above all, flexible winding at the end of a process.

The innovative stepped pintle of the VA- 800 from Kurre Systems ensures winding of spools with different bore holes without retooling. © Kurre Systems

The innovative stepped pintle of the VA- 800 from Kurre Systems ensures winding of spools with different bore holes without retooling. © Kurre Systems