05/11/2024 – Specialised machine manufacturer impresses with customised solutions

Winding technology – flexible like never before

Flexibility is desired in all areas of cable production - but realising this often is a major challenge. The topic of winding also falls into this category. Kurre Systems is producing a product family of fully automatic double winders with improved parameters and features for fast, reliable and, above all, flexible winding at the end of a process.

Designed for use within core extrusion lines, the winders offer a maximum winding speed up to 2,000m/min for coil sizes of 630mm or 800mm, depending on the upstream process. The two large coil magazines that can hold empty and full coils as well as two winding stations ensure a continuous production process.

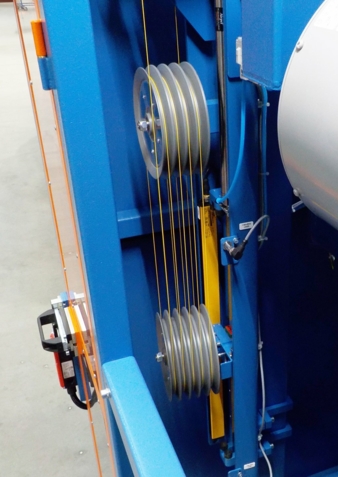

In terms of flexibility, the winders excel with their variably adjustable tension ranges. This is ensured by the integrated dancer, which enables multiple assignment of the deflection wheels. In this way, a tensile force range of 3N to 60N can be realised.

The development team also considered the issue of set-up times. For a wide range of coils with different bore holes, the use of the innovative electrically adjustable stepped pintle can be considered to ensure that set-up times are completely eliminated. With this optional solution, manual pintle change is no longer necessary and the production process does not have to be interrupted. The increase in OEE justifies the investment in a very short time.

In terms of handling, side doors allow easy access to the inside of the machine. The winding stations in particular are easily accessible. The machine is operated via a touch panel with the proven and intuitive software from Kurre Systems.

Kurre Systems

Industriestrasse 5

26683 Saterland/Germany

Contact person is Thorsten Wilde

Tel.: +49 4498 9250-120

thorsten.wilde@kurre-systems.de

www.kurre-systems.de