18/04/2023 – Surface treatment / Blasting

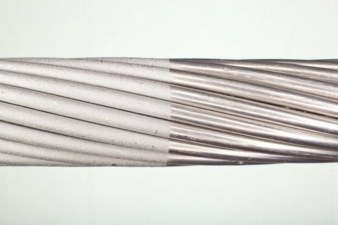

Wet blasting system for wire and cable finishing

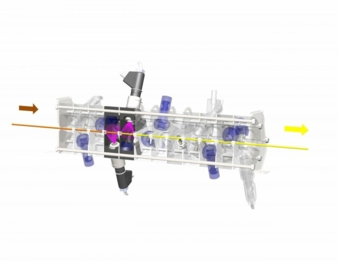

Designed specifically for the surface finishing of wire and cable, the automatic Vapormatt “Profelis” wet blasting system creates a highly clean reactive surface on wire, cable round bar and other strip products.

The “Profelis” with useful new features like an automatic door, integrated heating and drying and IIOT solution “Vapromatt 4.0”. © Vapormatt