08/02/2020

Upgrade on cage stranding machine

Increasing cost pressure and higher quality demands are forcing cable manufacturers to operate existing production systems more efficiently. Leoni Elocab in Georgensmünd (Germany), together with Baremo from Switzerland, has recently completed the upgrade of a cage stranding machine (including variable reverse rotation) with an FMS Force Measuring Systems AG (Switzerland) RTM Tension Control system.

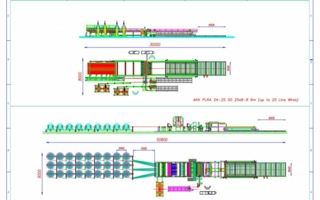

Leoni Elocab had preciously modified parts of the machine and equipped it with a modern control system. The machine, an 18-payoff Niehaus cage strander with two cages of 6- and 12-payoffs each, is used for the production of highly flexible special cables, some of which are produced in small batches (from 100m).

In the course of the upgrade an FMS “RTM X42.BC” telemetry system was included for continuous wire tension measurement and control was installed on the machine. The system has the capability to measure the tension on a maximum of 42 individual wires. A Control Center provides an overview, monitors limit values, manages recipes and creates quality protocols. The Brake Control ensures continuous and fully automatic wire tension control.

With the measures taken, the objectives of the audit were fully achieved. Plant productivity and process reliability were increased through continuous production without manual action in the control of the strand tension. For very low wire tensions, an efficient measuring and control system in the range of 2N to 20N is now available. Recipe management for individual products reduces set-up times, and the tension information is recorded for quality data acquisition and control. Also available at each payoff are digital inputs for use in monitoring Pintle Lock status or other safety or process related functions. The system makes strander operation easier for operators and auxiliary personnel.

The RTM X42 telemetry system measures the strand tension of individual wires in cage or tubular stranding machines. Both the machine operator and your quality management personnel have access to these process parameters.

Modular system for wire tension measurement

Strand tension values are displayed via the optionally available RTM X42.CC Control Center or in your existing PLC. Due to the standardized interface, the connection to your PLC can be easily realized with all common protocols covered via an Anybus Gateway. Many new machines are already delivered with the RTM X42 system. For existing machines, however, the system can also be easily retrofitted due to the modular system design and the compact components.

Measurement data by radio

The RTM X42 system transmits the measurement data by radio and the power supply is provided by high-performance and long-life rechargeable batteries; no slip rings are required. While each RTM X42 system can monitor up to 42 single wires or strands, the modular design of the system allows for multiple systems to operate in parallel. Thus, the number of monitored strands is practically unlimited.

FMS Force Measuring Systems AG

wire 2020, hall 11 booth J 09

Aspstrasse 6, 8154 Oberglatt/Switzerland

Tel.: +41 44 852 8080

norbert.schilling@fms-technology.com

www.fms-technology.com

Baremo GmbH

wire 2020, hall 11 booth J 05

Amriswilerstrasse 47, 8590 Romanshorn/Switzerland

Tel.: +41 71 4667000

info@baremo.ch

www.baremo.ch

Leoni Elocab GmbH

Business Unit Tailor-Made Products

Obere Lerch 34

91166 Georgensgmünd/Germany

Tel.: +49 9172 6980-0

machinery-sensors@leoni.com

www.leoni-machinery-sensors.com