05/11/2025 – Quality management

UFD40 – Precise Splice Detection for the Wire and Cable Industry

In the wire and cable industry, quality assurance is at the heart of every production line. Especially in areas with fast and continuous processes—such as the production of rods, wires, fuel lines, and cables—intermediate products with defects are often unavoidable. The challenge: Many of these defects remain hidden inside the material or at junctions. Optical detection is usually not reliable under such process conditions.

Non-Destructive Testing During Continuous Operation

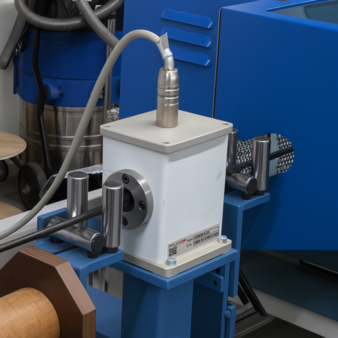

For this reason, modern, non-destructive inline material testing is indispensable—especially for identifying mechanical splices and other unwanted phenomena such as pores, cavities, or scoring marks. The eddy current-based testing and detection system from ROLAND Electronic, the UFD40, is specifically designed for continuous industrial use in wire and cable production lines.

Real-Time Measurement Using the Eddy Current Method

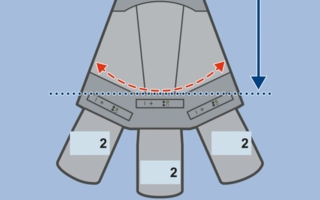

The measurement principle is based on the eddy current testing technique. A magnetic field is first generated using a coil. This induces eddy currents in the test object, which must be a conductive material (e.g., wire or cable). Material defects such as discontinuities or splices alter the flow of these eddy currents. This causes measurable changes in the magnetic field of the receiving coil. These changes are captured, filtered, and analyzed by evaluation electronics. A variation is identified as a “defect” when the filtered sensor signal exceeds a predefined threshold value. This process occurs continuously, contact-free, and in real time.

With a maximum sampling rate of 15kHz, the system achieves a spatial resolution of 0.6mm at material speeds of 10m/s. The autonomous measurement box transmits the measurement results via a fieldbus network or parallel I/O directly to the PLC of the overall system. With the “defect” signal and precise position information, appropriate corrective actions can be initiated.

Wide Range of Applications Thanks to Modular Design

The “UFD40” coil-based testing system has a modular design and supports material diameters from 1mm to 90mm as standard (larger diameters can also be implemented). The various sensors for specific test diameters are quick and easy to replace. The “UFD40” is multi-channel capable, with each channel functioning independently – performing measurement, evaluation, and real-time communication with the PLC.

The channels can operate autonomously in "standalone" mode or be controlled by an external PC in "remote" mode.

The “UFD40” from Roland Electronic is a powerful eddy current testing system for wire and cable manufacturers. It integrates seamlessly into existing production lines and reliably detects mechanical splices and other defects during ongoing operations – automatically and effectively reducing costly scrap production.

Roland Electronic GmbH

Otto-Maurer-Strasse 17

75210 Keltern/Germany

Contact person is Peter Eiswirt

Tel.: +49 7236 9392-0

info@roland-electronic.com