16/03/2022 – Combination of components into a single system

The integration of guiding and straightening

The new models “RKO VK A” and “RKO VK B” represent the revised series “RKO VK” of the Witels-Albert GmbH. Compared to the “RKO VK” models no longer in the product range, all rollers of the “RKO VK A“ and “RKO VK B” guides are designed to be adjustable.

The straightening results of long products such as wire, tube, rope and strip depend on the design of the sub-processes upstream and downstream to the straightening processes. Guiding is an important sub-process and is carried out with the objective of supplying and discharging a process material to and from the straighteners without collision. Boundary conditions such as the cross-sectional geometry of the process material, the variety of geometries and the design of the straighteners determine whether guiding is required taking into account the zero line or guiding with a fixed bottom and/or back edge.

Roller guides

Roller guides whose tools are rotatably mounted guide rollers are widely used. The design principles of guide rollers are influenced by the objective of minimising wear through surface removal or surface application. The cylindrical rollers can be made of different materials, be coated and be designed with or without profiling. The advantages over guides with stationary tools, such as guide bushings or pins, are a longer service life of the tools and protection of the process material surface.

Due to the diversity of boundary conditions, there are numerous models of roller guides equipped with fixed rollers, partially adjustable rollers or with individually adjustable rollers. Roller guides with individually adjustable rollers are popular and dominate the sales statistics.

New models “RKO VK A” and ”RKO VK B”

The new models “RKO VK A” and “RKO VK B” serve the trend. Compared to the “RKO VK” models no longer in the product range, all rollers of the “RKO VK A” and “RKO VK B” guides are designed to be adjustable. This means that they can be used on the infeed and/or outfeed side of straighteners with partially adjustable straightening rollers as well as of straighteners with individually adjustable rollers. And this is independent of the respective infeed variant “VW”, which is influenced by the transport direction of the process material, the spool or coil axis and the direction of rotation of the spool or coil.

All models consist of two identical main body parts, which are assembled to the main body by screw connections. The arrangement of the main body parts is individual and results in either a model “RKO VK A” or a model “RKO VK B”.

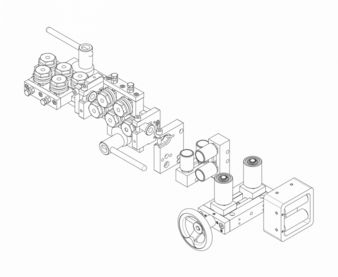

The integration of guiding and straightening, i.e. the combination of components for guiding and straightening process material into a single system, is achieved with two new sets of connecting brackets. One set serves “ER” and “RB” series straighteners and another set serves “RT” and “RTS” series straighteners. Each set is available for three guiding or straightening ranges determined by the process material thickness ranges of 0.5mm to 1.5mm, 1.5mm to 3.0mm and 3.0mm to 7.0mm. The connecting brackets can be used to connect the “RKO VK A” and “RKO VK B” roller guides to straighteners, or guides of the “RK”, “RK VE”, “RK VE SH” and “ZR” series.

The new standard represents high flexibility and agility for Witels-Albert as a manufacturer of systems for guiding and straightening. Interested parties can choose from a high number of variants, which are assembled in a short time to suitable, ready-to-install systems for guiding and straightening process materials. During the lifespan of the products, users benefit from the technical advantages, which also include the possibility of retrofitting the systems at any time.

wire 2022, hall 9 booth E 39

Witels-Albert GmbH

Malteserstrasse 151-159

12277 Berlin, Germany

Contact person is Marcus Paech

Tel.: +49 30 72398811

paech@witels-albert.com

www.witels-albert.com