02/04/2021 – Right equipment for each demand

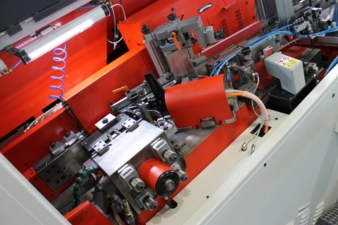

Sacma Group: WF headers product line

Sacma Group, already leader in the market of headers for special materials, completes its range of machines with the new "WF line" and is now able to supply the right equipment for every need, especially for aerospace and other markets.

The 5 and 6 die headers WF are size 2 (wire max 10,5mm) , size 3 ( 15mm ), size 4 (20mm) and size 5 (25mm): © Sacma

RP420-WF (TR4/W20) : With the new WF line, Sacma Group, completes perfectly its whole range of machines. © Sacma

RP220-WF (TR2/W10): Sacma now is able to provide the right equipment for each demand especially for the Aerospace and other markets. © Sacma

The 5 and 6 die headers WF are size 2 (wire max 10,5mm) , size 3 ( 15mm ), size 4 (20mm) and size 5 (25mm). © Sacma

The 5 and 6 die headers WF are size 2 (wire max 10,5mm) , size 3 ( 15mm ), size 4 (20mm) and size 5 (25mm): © Sacma

The 5 and 6 die headers WF are size 2 (wire max 10,5mm) , size 3 ( 15mm ), size 4 (20mm) and size 5 (25mm): © Sacma