15/01/2020

Rolling ring drive ready for Industry 4.0

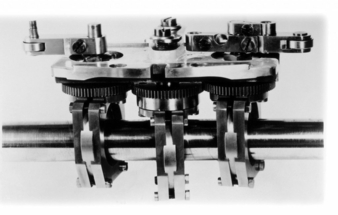

Uhing is the synonym for continuous development and innovation. This has been so for nearly 70 years. As early as in 1952, the company founder Joachim Uhing, by inventing the rolling ring drive, satisfied a user’s wish from the winding and traversing sector for the perfect linear drive.

He launched the world’s first version on a plain round shaft. The world has changed since then. But Uhing’s approach remains unchanged.

Continuous adaptation to constantly changing industrial demands is the recipe for the success of Uhing’s rolling ring drive. In the 1950s, close cooperation with knitting machine manufacturers gave the decisive impetus to Joachim Uhing. The engineer recognised his customer’s wish for automating the reciprocating travel of a knitting carriage performed manually so far and came up with a trendsetting novelty that should prove to be successful in the long run.

In the course of years, the Uhing rolling ring drives became more powerful and could be adapted to general drive needs of other industries. To meet automation demands, additional electronic control units were additionally developed in the late 1990s, ultimately leading to the fully developed Uhing Motion Drive in 2016.

Entirely in the spirit of Industry 4.0, the UMD variant is not just “purely” electronic – essentially, the Uhing Motion Drive is still a mechanic rolling ring drive where, however, scale and reversing lever have been omitted physically and a stepper motor and an electronic control unit were added. Apart from the programs standardised for winding applications, other user-specific programs can also be loaded, which makes the Uhing Motion Drive a highly flexible drive for general applications. In addition, the specifications and possibilities of the mechanical processes can be emulated electronically.

Uhing has continuously developed the proven rolling ring principle after many discussions with industrial customers – for example, from the paper processing or food industries. The Uhing Motion Drive makes many things possible – and can be extended step by step for production-related modernisations. For example: one control unit can control and monitor several systems in parallel. Wolfgang Weber, Uhing’s Managing Director: “Whether it’s for use in new machines or for converting and upgrading existing systems – with Uhing Motion Drive, we meet our customers’ requirements for digitalization of mechanical automation processes. In this way, we are working at the forefront in order to ensure a sustainable future of linear drives.”

Joachim Uhing GmbH+Co. KG

wire 2020, hall 11 booth B 40

Konrad-Zuse-Ring 20

24220 Flintbek/Germany

Contact person is Wolfgang Weber

Tel.: +49 4347 906-22

weber@uhing.comwww.uhing.com