28/10/2021 – Welding speeds of up to 150 crosswires per minute

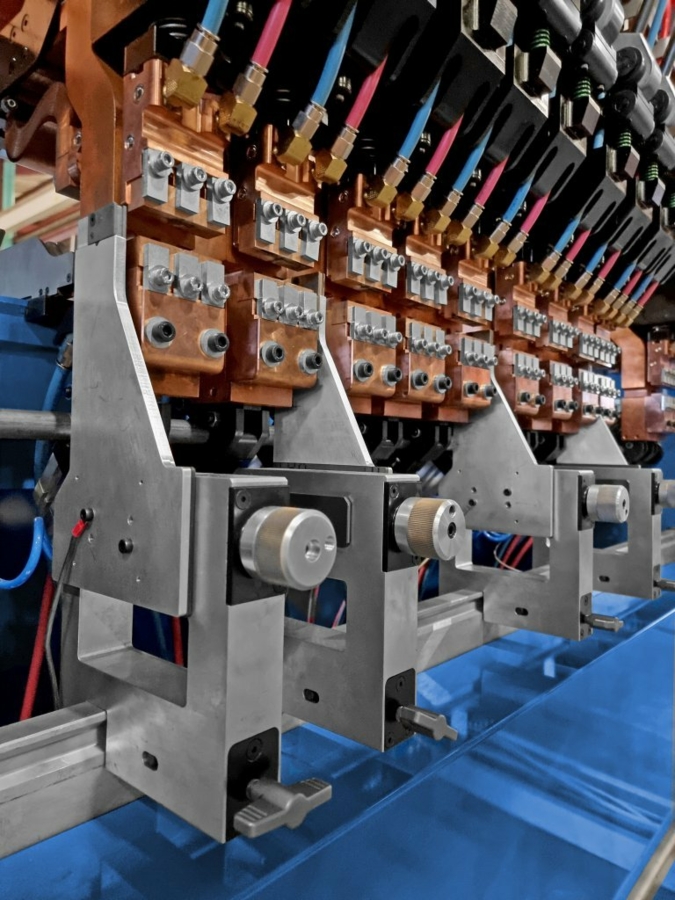

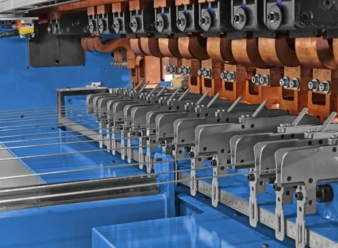

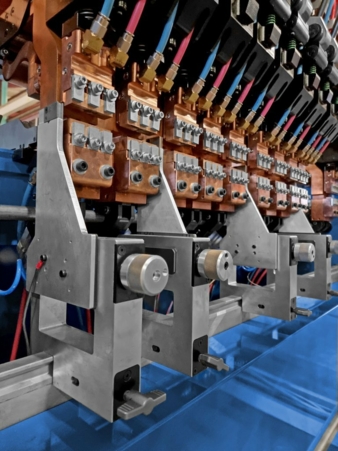

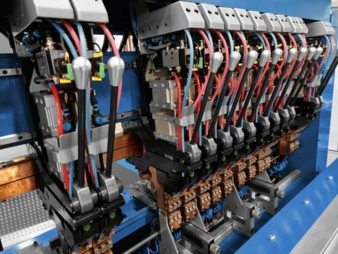

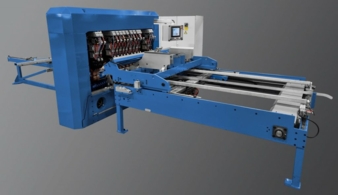

QSW mesh welder

Clifford’s Quick Change Mesh Welder is designed to take the guesswork out of mesh panel manufacturing. Laser-guided tooling setup ensures quick product changeovers, and the frontend software automatically calculates the optimal weld settings for each recipe. All this new technology is packed into their latest “QSW” mesh welder.