28/10/2021 – Welding speeds of up to 150 crosswires per minute

QSW mesh welder

Clifford’s Quick Change Mesh Welder is designed to take the guesswork out of mesh panel manufacturing. Laser-guided tooling setup ensures quick product changeovers, and the frontend software automatically calculates the optimal weld settings for each recipe. All this new technology is packed into their latest “QSW” mesh welder.

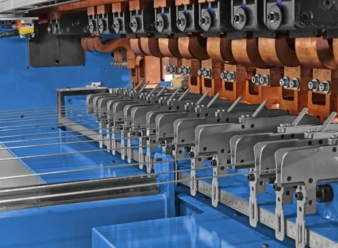

The operator creates a drawing of the new mesh panel on the screen. The machine scans and detects the existing position of the linewire guides and weld elements on the machine. With the new recipe as input, the machine calculates the optimal position of all the components on the machine.

Using laser guidance, the machine takes the operator through a step-by-step process to set up the components. These include the linewire guides, the weld presses, magnets and sensors, as well as the pull-out grippers.

The easy-glide welding arrangement is operated by a single locking lever. Each weld element uses guide arrow lights for identification and direction adjustment confirmation. No tools are required.

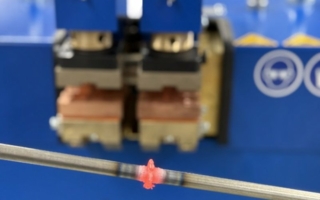

Each 75mm weld element can weld up to 3-line wires at a time. MFDC – (Medium Frequency Direct Current) welding is standard for fast high-quality welds.

Magnet and gripper positions are calculated by the frontend and are equally easy to set with no tools required. Ruler guides are attached to the tooling to ensure positioning is exact.

Software powered by A.I.

Trial and error software setup is a thing of the past with our AI-powered frontend. AI automatically calculates the optimum settings for welding current, welding pressure, weld time, and weld squeeze for each recipes wire diameters. The simple touch screen interface will guide the operator with step-by-step wizards and 3D modelled illustrations.

All recipe settings can be fine-tuned and saved, along with acceleration speeds and positions for future use.

Flexibility

Product flexibility, consistent weld quality and quick changeover times are what the machine has been designed for. With welding speeds of up to 150 crosswires per minute, and only 1 operator required to run the machine, customer can be assured a great return on investment.

Ready, set, weld

Now that the machine is set up in record time customer can get down to production. All their machines come with a 1-year guarantee, and they have a global spares and support distribution network. Clifford only uses the best and most reliable components like Beckhoff, Festo and Rexroth. Specialist technicians are always on standby via telephone and internet remote support. Onsite support is also available if customer just can’t solve the problem. Their spares and support team ensures downtime is kept to an absolute minimum.

All this technology is packaged together to make the Clifford QSW stand far above their competition. Providing fast, automated, reliable and cost-effective machinery to any wire mesh manufacturer. With over 50 years of experience in the mesh-welding industry, customer can rely on a Clifford machine.

Clifford Machines+Technology PTY LTD

24 White Road, 3201, Pietermaritzburg, South Africa

Contact person is Iain Ambler

Tel.: +27 333 553410

ambleri@cliffeng.com

www.cliffeng.com