19/10/2025 – Tools

Precision engineering with TW and Nano pressure dies

Since 1962, Ajex+Turner Wire Technologies has been a trusted partner to the global wire and cable industry. Over six decades, the company has combined Indian manufacturing strength with international expertise to deliver innovative die solutions that meet the toughest demands of modern conductor production.

Today, two products stand out as defining its leadership: TW Dies and Nano Pressure Dies.

TW Dies: Setting Standards for Sector Conductors

As the power sector evolves, utilities and manufacturers are moving beyond traditional round conductors to sector and trapezoidal shapes. These designs allow more aluminum to be packed into the same diameter, improving conductivity and reducing line losses—critical for efficient transmission networks.

Ajex+Turner’s TW Dies, available in PCD and carbide, are designed specifically for this challenge. They shape aluminum strands into precise trapezoidal and sector profiles with smooth surfaces that comply fully with ASTM standards. These dies are used worldwide

to manufacture conductors such as ACSR, ACCC, ACSS, and ACFR, all approved by major power utilities.

A key strength of TW Dies is their ability to enlarge trapezoidal profiles while keeping diameters consistent with conventional round conductors. This innovation means greater cross-sectional area – and thus higher current capacity – without creating compatibility issues. Manufacturers benefit from reduced wastage, easier compacting, and reliable conductor performance.

Ajex+Turner also brings technology into the process. By using AI-based modelling, the company predicts shrinkage factors in tooling before production even begins. This ensures the final geometry matches specifications from the very first run, saving time and cost while guaranteeing quality.

Nano Pressure Dies: Innovation in Dry Drawing

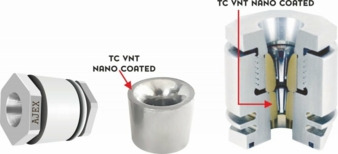

While TW Dies reshape how conductors are built, Nano Pressure Dies are redefining the drawing process itself. Designed for dry drawing applications, these dies feature a dismantlable three-part construction: a strong steel casing, a tungsten carbide pressure die, and a nano-coated carbide nib that can be quickly replaced.

The innovation lies in the nano coating. Unlike traditional dies that wear quickly, these nibs provide improved lubrication, tighter tolerances, and significantly longer life. They deliver a consistently smooth wire surface, essential for high-speed production. Practicality is also built in: since the nibs are lightweight and compact, they can be shipped in large quantities at lower cost, avoiding the logistical burden of heavy casings.

For manufacturers, this means less downtime, lower maintenance, and a more efficient drawing process. It’s a solution designed for today’s high-output wire plants that cannot afford interruptions.

Global Recognition

Ajex+Turner’s dies are trusted not only in India but across Asia, Africa, the Middle East, Europe, and the Americas. Their products are approved by leading power grid corporations and are already in service across some of the world’s most demanding projects.

Shaping the Future

Together, TW Dies and Nano Pressure Dies showcase Ajex+Turner’s approach: combine deep materials knowledge with customer-focused design and predictive technologies to create tools that raise industry standards. Whether it’s enabling efficient, ASTM-compliant conductors or streamlining wire drawing with longer-lasting dies, Ajex & Turner continues to strengthen the backbone of power transmission worldwide.

Cable & Wire Fair 2025, booth 5/D1-1

Ajex+Turner Wire Technologies Pvt Ltd.

A-53, G. T. Karnal Road, Azadpur, Delhi 110033/India

Tel.: +91 98113 78882

sales@ajexturner.com

www.ajexturner.com