10/06/2022 – Automated winding system for ultra-fine wires

Perfectly wound ultra-fine wires

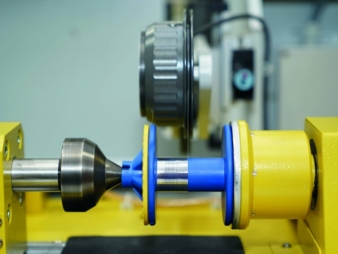

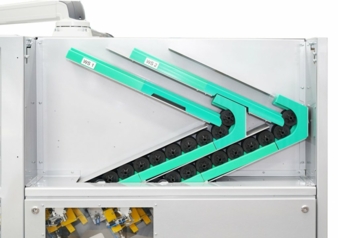

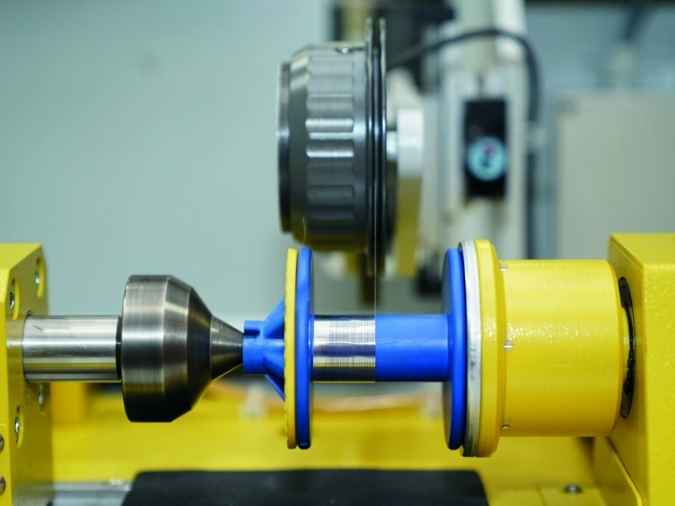

Kurre Systems has launched a new automated winding system for ultra-fine wires from diameter 0.05mm onwards. The machine consists of a pay-off unit and a take-up unit.

The Kurre braid winder perfectly winds ultra-fine wires from 0.05mm and prepares them for the braiding process. © Kurre