04/12/2024 – “IM-ECO“ by EVG convinces at Tammet Oy in Finland

New welding system for the production of fence and industrial mesh

As a specialist for the production of welded grids, the Finnish company Tammet Oy has purchased the newly developed “IM-ECO” welding system from the Austrian machine and plant manufacturer EVG in the course of “wire 2022”. Two years later, both sides enjoy a production performance that has even exceeded the already high expectations.

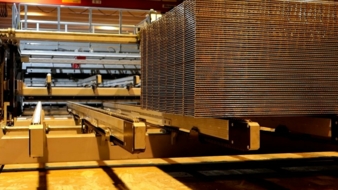

The new EVG welding system “IM-ECO” for the production of fence and industrial mesh inspires Tammet Oy in Finland. © EVG

The new EVG welding system “IM-ECO” for the production of fence and industrial mesh inspires Tammet Oy in Finland. © EVG

Product Manager Thomas Kügerl, EVG; CTO Stefan Källberg and Production Manager Fredrik Björkmann, Tammet Oy; EVG Representative Taneli Raivio, Tesproma. © EVG