22/11/2024 – The “MELC Polyline” series with simultaneously operating straightening rotors

Multi-line wire straightening machines

Outperforming any conventional straightening method and machine. Unique concept from Eurobend with multiple, simultaneous working straightening rotors with hyperbolic rollers.

Three-line machine, model “MELC 2-10x3” with mechanical stop length precision measuring system. © Eurobend

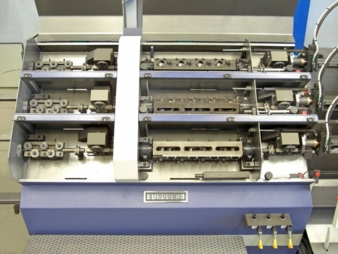

Three-line machine. View of the rotor system. Each rotor covers a different diameter range. © Eurobend

Three-line machine, model “MELC 2-10x3” with mechanical stop length precision measuring system. © Eurobend

Three-line machine, model “MELC x3 MS” with mechanical stop length precision measuring system. © Eurobend