16/09/2020 – Wire drawing

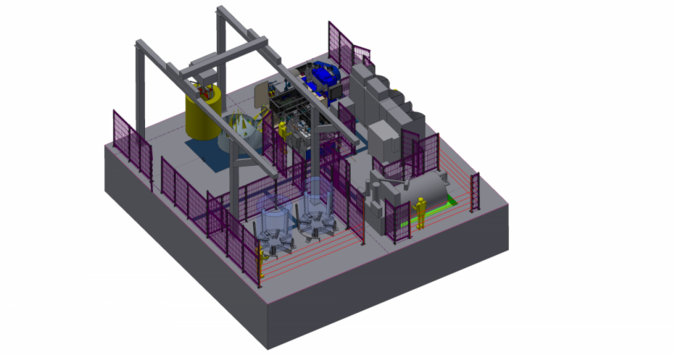

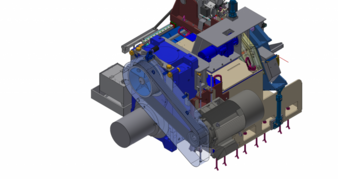

Modular drawing lines for large diameters

The long history of the company Kieselstein involves the successful manufacturing of plants for the processing of big diameter wire. This is used for cold heading parts, springs and similar components used amongst others in the automotive industry.

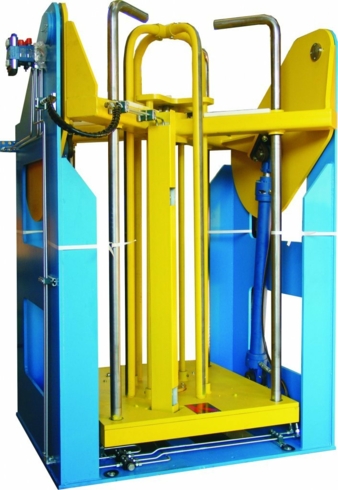

Fig. 3: Horizontal (left) and vertical (right) wire coil pay-off – both offer advantages. © Kieselstein

Fig. 3: Horizontal (left) and vertical (right) wire coil pay-off – both offer advantages. © Kieselstein