07/12/2021 – “Digital Assistant+” helps to optimise the operation of Niehoff machinery

Making full use of performance potentials

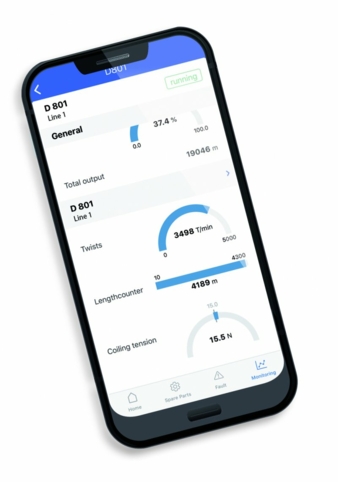

The Niehoff Digital Assistant+ app developed by Maschinenfabrik Niehoff supports the users of Niehoff machinery in the areas of management, production, purchasing and maintenance. The app can be used on PCs and / or mobile devices with Android or iOS software platforms. In its current version, the app contains three modules.

With the Niehoff Digital Assistant+ “Basic” module, which is free of charge, the causes of malfunctions can be detected ("Trouble Shooting"), spare parts can be quickly and easily identified and related inquiries can be sent to the Niehoff service with just two clicks.

The “Premium” module helps with machine malfunctions and supports communication with the Niehoff service in order to handle easily and directly error messages.

The “Machine and Process Monitoring” module shows the Key Performance Indicators (KPI), gives the user a clear picture of the machine condition and its temporal development, and supports predictive maintenance as well as process monitoring.

Advantages for the users

The Niehoff Digital Assistant+ app is an indispensable aid if a user of Niehoff machinery wants to increase the overall system effectiveness (OEE) of a machine or line. It makes machine and production processes transparent. Consequently, the user gets the opportunity to identify critical developments at an early stage and to react quickly to them. As one user said, on the one hand the app is a very good monitoring tool because he has access to the current status of the most important production parameters whenever and wherever he wants to. On the other hand, activities such as service calls, maintenance measures and repairs can be scheduled in time, thus reducing unscheduled downtimes. In addition, the app can help to optimise ordering and storage of spare parts.

From the beginning of April 2021 onwards, all new Niehoff machines to be delivered to Europe are equipped with the Niehoff Digital Assistant+ “Basic” module.

Complete solutions from a single source

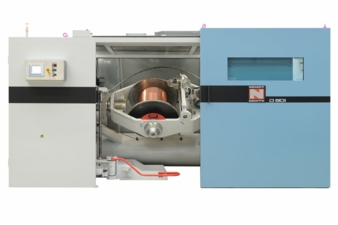

With an experience of 70 years in the wire and cable industry, Maschinenfabrik Niehoff develops and builds machinery needed for the production of non-ferrous wires and their downstream processing into automotive, power, data and special cables – the only exception are extruders. Additionally, the company provides technical assistance by experts speaking the customers´ languages, and reliable supply of OEM wear and spare parts.

Professional machinery inspections, competent maintenance, refurbishment and upgrading measures as well as machine operator and maintenance training courses imparting sound knowledge, are also part of the available services. Remote commissioning and relocations of Niehoff machinery on the customer’s site complete the wide range of Niehoff services. Niehoff Group offers custom-tailored solutions from development and planning to turnkey projects of complete cable factories.

Niehoff meets the daily challenge of minimising the consumption of resources and of contributing to the protection of the environment. Niehoff delivers products that help their customers to reduce energy consumption.

Niehoff joined the “Blue Competence” sustainability initiative of the German Engineering Federation VDMA and commits itself to complying with the twelve Sustainability Guidelines of the Mechanical Engineering Industry (www.bluecompetence.net). With a view to corporate social responsibility (CSR), Niehoff also cooperates with EcoVadis, an international platform for sustainability ratings.

Niehoff Group with over 950 employees worldwide is comprised of the headquarters, six manufacturing subsidiaries (in Brazil, the USA, the Czech Republic, India, China, and Sweden) as well as sales and service centres in Japan, Singapore and Russia.

Maschinenfabrik Niehoff GmbH+Co. KG

Walter-Niehoff-Strasse 2, 91126 Schwabach, Germany

Contact person is Norbert Meyer

Tel.: +49 9122 977-291

info@niehoff.de

www.niehoff.de