28/03/2024 – Wire processing / Measurement

Intelligent removal of isolation from hairpins

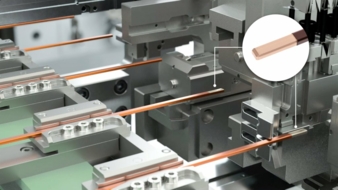

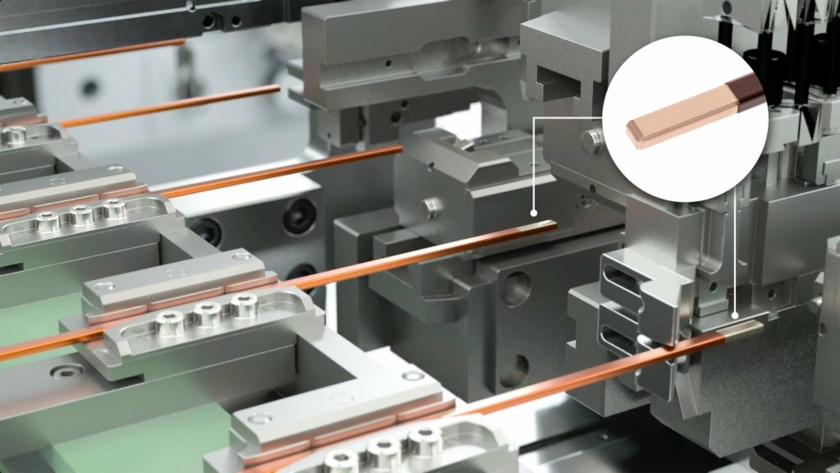

Thanks to a new process, Germany-based Otto Bihler Maschinenfabrik is making the removal of isolation from hairpins even more reliable and efficient. The solution centers around an innovative sensor unit, which continuously measures the enameled copper wire.

The new sensor system permanently measures the thickness of the enamel coating and the combined thickness of the coating and the copper wire. © Bihler