28/03/2024 – Wire processing / Measurement

Intelligent removal of isolation from hairpins

Thanks to a new process, Germany-based Otto Bihler Maschinenfabrik is making the removal of isolation from hairpins even more reliable and efficient. The solution centers around an innovative sensor unit, which continuously measures the enameled copper wire.

The downstream isolation removal station then uses this data to strip the isolation from each hairpin individually and with the utmost precision – with minimum loss of cross-section and in a way that ensures pure metal surfaces.

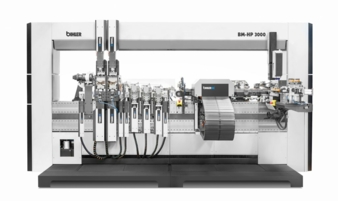

The manufacture of hairpins has long been one of Bihler’s core fields of expertise. After all, these correspondingly shaped parts made from enameled copper wire are firmly established components in electric motors and demand for them has grown greatly in recent times due to the increasing popularity of e-mobility. That is why Bihler recently developed the BM-HP servo system. This is a fully automatic, end-to-end system that can manufacture up to 120 hairpins per minute and also permits “on-the-fly” variant changes. The system guarantees absolute dimensional accuracy at the level of head shape, length and parallelism of the individual pin legs and, most importantly, guarantees the reproducibility of the 3D head geometry of each pin.

Precisely measured material removal

At the same time, Bihler is concentrating on further developing its hairpin manufacturing process. One particular challenge lies in removing the isolation from the ends of the pins. “The important thing is to produce a pure metal surface at the ends of the pin legs that is completely free from any enamel residue. At the same time, the cross-section of the copper wire must only be marginally reduced by the stripping-off of the enamel coating,” explains Martin Lehmann, Bihler Key Account Manager E-Mobility. This is particularly important from a safety perspective because inadequate leg cross-sections would result in unwanted heating at the connecting points. However, it is equally vital that the coating is stripped away cleanly and without residue because the pin ends have to be completely free from contamination if they are to be welded at the stator plate following assembly. The task of stripping the isolation from the ends of the hairpins is made more difficult by the fact that very many different enamel and coating variants may be applied to the copper body. The tolerances of the copper wire must also be taken into account. What is more, the center of the copper wire is often slightly offset in the enamel coating, which is itself not of a uniform thickness. To compensate for these tolerances and reliably obtain a pure metal surface, it is necessary to remove a corresponding amount of material – unfortunately with the exact unwanted effect of making the cross-section too small and wasting a lot of valuable material.

Mechanical engineering at its best

This is the context in which Bihler developed the isolation removal station. This shuns the conventional laser beam-based approach and instead works purely mechanically. What is more, the enamel used to coat the surface that is to be stripped is unimportant: “We can shave off any coating,” stresses Lehmann. “This allows us to produce an extremely high-quality surface while also working with the utmost precision.” The isolation removal station includes a function for holding down the wire, a cutter arm and the corresponding cutter. It is located both at the front and back of the BM-HP, making it possible to strip both ends of the hairpins.

Innovative sensor technology

Bihler has now also developed an innovative and completely new sensor unit. This performs continuous inline measurements of the thickness of the enamel coating and the combined thickness of the coating and the copper wire. Using this data, it is then possible to control the isolation removal station extremely precisely via a control circuit. Lehmann makes things clear: “We do not have to strip any set amount from the copper wire in order to comply with a safety margin and can instead remove exactly as much of the coating as needed in order to get down to the actual wire dimensions. This guarantees a pure metal surface with only minimum cross-sectional losses even when the thickness tolerances fluctuate. It is an intelligent process that greatly boosts process reliability.” The purity of the metal surface has been confirmed by many detailed images captured using a scanning electron microscope.

Each hairpin processed individually

All the measured material values that are recorded by the sensor unit are passed on to the isolation removal station’s NC motors via a so-called shift register. At the station, the isolation is stripped from each hairpin individually at a rate of up to 120 parts per minute. The solution is easily able to cope with an extremely wide variety of enamel and wire variants and the total cross-sectional loss is generally less than 0.05 millimeters. And the solution offers yet another bonus: The four-sided chamfering of the ends is also integrated in the overall process. It also ensures the residue-free separation of the front surfaces thanks to an internally developed stamping process and the use of special die geometries. The finished hairpins are then ejected from the machine and assigned to different storage locations depending on their specific type. The Bihler solution for the removal of isolation on hairpins has already been patented and is available to all customers with immediate effect.

wire 2024, hall 10 booth F 18

Otto Bihler Maschinenfabrik GmbH+Co. KG

Lechbrucker Strasse 15, 87642 Halblech/Germany

Contact person is Vinzenz Hörmann

Tel.: +49 8368 18-280

vinzenz.hoermann@bihler.de

www.bihler.de