20/02/2021

How manufacturers of wiring harnesses can ensure traceability

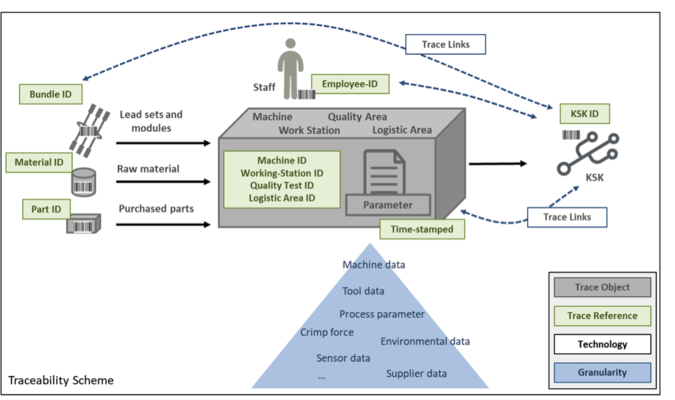

With the rise of autonomous driving and electrification, manufacturers of wiring harnesses will soon be confronted with completely new quality requirements. By using digital replicas of their products (also known as digital twins), manufacturers can trace their wiring harnesses constantly and thus rectify errors quicker or prevent them from happening in the first place. However, these twins cannot be implemented using the current process flows, which have to be adjusted on an operative, technical and organizational level.