20/02/2021

How manufacturers of wiring harnesses can ensure traceability

With the rise of autonomous driving and electrification, manufacturers of wiring harnesses will soon be confronted with completely new quality requirements. By using digital replicas of their products (also known as digital twins), manufacturers can trace their wiring harnesses constantly and thus rectify errors quicker or prevent them from happening in the first place. However, these twins cannot be implemented using the current process flows, which have to be adjusted on an operative, technical and organizational level.

The dawn of the electrified, self-driving car represents a paradigm shift for manufacturers of wiring harnesses. Once seen solely as commodity products, wiring harnesses are now becoming safety-critical components. They are used for running an increasing number of energy, signal and communication flows that support safety-critical functions such as steering, lane changes or braking. Problems with the electric systems can lead to serious malfunctions that not only result in the possibility of significant material damages, but also a risk to life and limb, not to mention hazards for the environment and the public.

It will thus become more important than ever for manufacturers of wiring harnesses to identify the causes of a problem quickly, rectify them and be able to start immediate, targeted product recalls. Only then is it possible to restrict potential hazards quickly and minimize image damage – both in terms of the reputation of the manufacturer of wiring harnesses at the vehicle manufacturers and the reputation of the vehicle manufacturers at the end customer.

However, this aspect is also of great importance on an economic level, as it can in some cases ultimately decide whether 100 or 100,000 vehicles have to be recalled. If errors can be isolated specifically, manufacturers then do not have to recall an entire vehicle series. Instead, the recall is limited to exactly those vehicles where the identified defective parts are installed. The fact that product recalls in the automotive industry have increased threefold in recent years shows just how important this topic currently is [1]. The average cost per recall amounts to around 12 million euros. However, the sums involved can easily reach billions, as seen in the case of defective Takata airbags. The product recall here led to damages totaling 25 billion US dollars [2].

Of course, the best option is to avoid errors in the first place. This not only enables manufacturers of wiring harnesses to eliminate the possible dangers, but also the risk of paying heavy fines. This is because liability in the era of autonomous driving is now shifting from the driver to the manufacturer, its suppliers, and even individuals within the value chain. If a malfunctioning wiring harness causes an accident in an autonomous vehicle, the manufacturer can expect a fine that could reach hundreds of millions of euros. This pressure is reflected in standards that address the topic of traceability in increasing depth. These include IATF 16949:2016 and ISO 26262, plus the VDA standards 5005, 4994, 4958 and 5600.

Creating digital replicas of wiring harnesses

With this in mind, seamless product traceability is now unavoidable for manufacturers of wiring harnesses. This can be achieved with the help of digital twins. These are digital replicas of the wiring harnesses that contain interlinked, consistent data records and enable manufacturers to trace their products across their entire life cycle. Digital twins cover two dimensions here. Firstly, they cover the product history, which allows the composition of a wiring harness to be reconstructed and thus ensures vertical traceability. Secondly, they also cover the process history, meaning the value chain can be reproduced and thus ensures horizontal traceability.

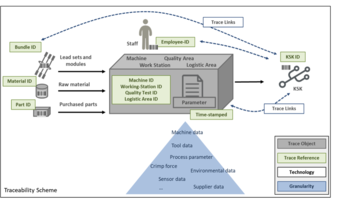

In terms of the product history, the digital twin compiles the raw materials, parts produced in house and purchased parts that have been used during the production of a wiring harness. This allows the manufacturers to localize errors, rectify them and provide the vehicle manufacturers with data for fast and very specific product recalls. With the process history, the digital twin receives information on how the wiring harness has been created, including the process steps and process parameters that have been implemented in order to produce the wiring system. This includes the force used during crimping, tool changeovers, post processing measures or the results of quality tests. Based on this holistic data, the quality of the wiring harnesses can be continually improved with the help of predictive analytics.

These digital twins can be implemented with manufacturing execution systems (MES), which communicate with the machines, employees and ERP systems involved in the process. The role of the MES has always been to control, inspect and document the production process, which makes it predestined for use with digital twins. However, the quality here also depends to a large extent on the configuration of the actual physical procedure that provides the MES with data. This procedure is currently not yet able to provide the information necessary for ensuring seamless traceability.

Production takes place in complex networks

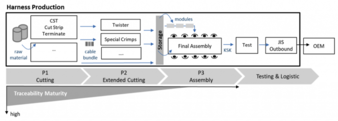

Nowadays, wiring harnesses are produced in complex networks made up of several companies, production sites and countries. These usually also include companies from North Africa and Eastern Europe, which leads to significant differences in terms of culture, process structure and quality awareness. However, the production of a customer-specific wiring harness (KSK) usually always follows the same basic process involving the three steps cutting, pre-assembly and final assembly – which are also known as production areas P1, P2 and P3.

In the first production area, the wires are cut in a highly automated process. Machines cut the wires to a specific length, strip off the sheathing and apply connectors. More complex machines can also perform additional process steps and twist the wire, for example. The wire pieces are then grouped into bundles and made available to the next production area P2. Here, the wires are pre-assembled and then assembled into simple kits using procedures such as crimping, welding and twisting. This is carried out at semi-manual workplaces.

These first two steps – cutting and pre-assembly – are usually carried out in advance and the wires stored in reserve. The pre-assembled products are manufactured in batches based on sales forecasts and then stored in a warehouse as buffer stock. The final products (in this case, the KSK) are then manufactured based on definite customer orders. To do this, the pre-assembled components and necessary purchased parts are taken from the warehouse and transported to P3 for final assembly. Here, they are assembled by hand on assembly boards. The final products are then packed and delivered to the vehicle manufacturer “Just in Sequence”.

When it comes to tracing the wiring harnesses, the maturity of the process flows constantly decreases from P1 to P3. In the first two production areas, the raw materials are scanned at the batch stage, process characteristics such as crimp force recorded and the wire bundles labeled with unique barcode IDs. However, in the third production area the bundles are split up and installed without scanning. The kits and modules are mounted without saving the bundle IDs or raw material IDs. This means that once the parts leave the warehouse they are installed completely anonymously, meaning the customer-specific wiring harnesses can no longer be traced.

One of the main reasons for this is that the manual processes seen in production area P3 significantly complicate both the recording and evaluation of data. This is in addition to the high complexity of the final assembly. On one hand, the vehicle manufacturers constantly change the design of the wiring harnesses themselves in order to further optimize them or modify them according to the features of a new vehicle model. On the other hand, suppliers of electric and sensor-based components also make constant changes to their products, resulting in subsequent adjustments to the wiring harnesses. Furthermore, cars are also configured individually by the end customer – particularly in Germany – meaning a matching wiring harness is also required. The end customers usually have the opportunity of changing their configuration until shortly before the car is manufactured. This all means that virtually every wiring harness has to be produced in a batch size of one, resulting in millions of variations and the manufacturers of wiring harnesses being confronted with up to 1,000 modifications per day. This complexity makes standardization of the processes more difficult, prevents process stability and often leads to firefighting measures and ad hoc management.

Process flows in need of change

It is thus clear that continuous traceability is not feasible with the current process flows. In order to provide the necessary information for the digital twins of the wiring harnesses, they have to be adjusted on an operative, technical and organizational level. In terms of operation, the procedure has to be expanded to include steps such as the scanning of products or the documentation of quality inspection results. Ideally, this is made by stationary scanning systems or automated documentation via the machines. This ensures only minimum extra work is needed in the workflows and human intervention is kept to a minimum. Furthermore, the introduction of principles such as FIFO (first in, first out) and poka-yoke significantly reduces the number and complexity of additional process adjustments. Nonetheless, the digital twins still require suitable devices in order to capture the data relevant for traceability. In terms of technology, this can mean the installation of scanners or updates and the reconfiguration of machines.

Additionally, trace objects have to be selected and equipped with traceability technology such as barcodes or RFID. These trace objects indicate relevant elements such as components, materials, machines and workstations. Each of these objects must be made identifiable using a trace reference, typically through the assignment of unique identifiers (IDs) to physical objects. When traceability technologies such as barcodes or RFID are used, these IDs then allow for a virtual replica of the components, materials, machines and workstations to be made. Process parameters such as crimp force, tool changeover, post processing or quality tests are dynamic trace objects and thus cannot be referenced with a unique ID. In this case, the referencing should be made with the help of time stamps.

In addition to operative and technical aspects, organizational awareness also plays a decisive role when it comes to the quality of the digital twins. Employees can no longer scan several products in advance instead of each individual product during assembly, or scan the same product multiple times in place of the different parts that are actually used. If there is a lack of discipline when carrying out the processes, this will lead to incorrect and inaccurate records.

Flexible MES are required

It goes without saying that the necessary adjustments to the process and the resulting modernization and further automation of production cannot be achieved overnight. Nonetheless, manufacturers of wiring harnesses should not put off this step any longer. Taking the necessary steps to ensure a smooth transition will probably take years, and is something that should be put into action today. It is the responsibility of the MES providers to develop solutions that can offer flexible support to manufacturers on each step of the transition process. In this way, they should be able to first establish vertical traceability by recording all important purchased parts and components involved in the customer-specific wiring harnesses. These include the batch IDs of the harnesses used, the IDs of the purchased components with the supplier IDs, and the unique IDs of the processors and their software versions. Additionally, important horizontal traceability records also have to be included, such as machine and tool IDs, production times, quality results and reworking.

By adding further quality-related process data such as machine parameters or sensor data, these data records can then be expanded step by step into complete data records. This not only allows manufacturers to use predictive analytics to determine which components will fail, when and in which circumstances – thus avoiding errors in the first place, increasing product quality and enhancing their competitive strength. Based on this holistic data, many other helpful applications can also be established. For example, manufacturers of wiring harnesses have the opportunity of optimizing their production and thus enhancing profitability. This can be achieved by using the data to tune machines and letting them run faster without sacrificing on quality, for example, or by using overarching data to synchronize the pre-production and final production processes with one another. This means that only a certain percentage of cutting and pre-assembly work has to be made in advance, with the rest made according to specific customer orders. In this way, manufacturers can achieve an optimal balance between keeping machine utilization as high as possible and warehouse stock as low as possible. Finally, the data from the digital twin can also be analyzed and visualized in real time by production staff and management so that the processes can be constantly monitored. This allows them to intervene when needed in order to ensure business excellence and high profitability.

Bernd Jost, DIIT

[1] Federal Office for Motor Traffic (KBA), 2017

[2] Allianz Global Corporate Speciality SE – Product recall: managing the impact of the new risk landscape, 2017

DIIT GmbH

Justus-von-Liebig-Ring 11a

82152 Krailling/Germany

Contact person is Patricia Lange

Tel.: +49 89 8932500

patricia.lange@diit.de

www.diit.de