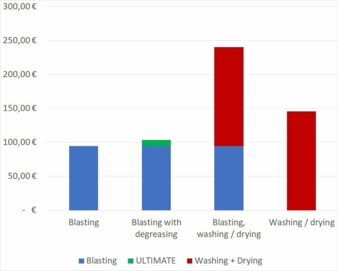

01/03/2024 – Reducing costs and energy consumption in blasting

Higher Overall-Equipment-Effectiveness

Improving the cost-effectiveness of production processes has always been an important task, especially to increase your own competitiveness. In the recent past, this need has become even more pressing. The reduction of energy consumption, and thus of the costs for gas and electrical power, has taken on a completely new dimension.