24/10/2023 – Winding technology for the production and processing of fine wire or optical fibres

High-precision positioning and winding

Supertek sets new standards in winding technology for the production and processing of fine wire or optical fibres.

The coil scanner “TDS” detects the geometry of the wound coil during winding. The non-contact measurement of the coil is used for automatic winding for perfect windings on conical coils. © Supertek

The coil scanner “TDS” detects the geometry of the wound coil during winding. The non-contact measurement of the coil is used for automatic winding for perfect windings on conical coils. © Supertek

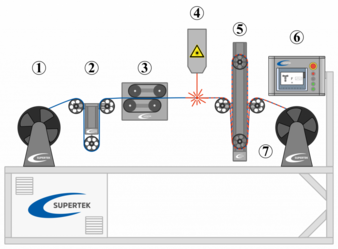

Machine for automatic processing of highly sensitive optical fibres and glass fibres. Used for various purposes, including laser processing in research and industry. © Supertek