16/04/2019

Henan Tongren orders Tenova aluminium strip processing line

Henan Tongren Aluminium Co. Ltd – Chinese manufacturer specialised in the production of aluminium products – has awarded Tenova with a new contract for a continuous annealing and chemical pre-treatment line for processing strip coils for aluminium market, to be realised in Sanmenxia/China.

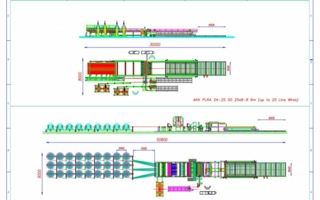

Castellanza/Italy (Tenova) – This adds up to over fifteen references in China, North America and Europe. The new line will process automotive and aircraft aluminium alloys, family series 2XXX, 5XXX, 6XXX and 7XXX, with a strip width range from 1000mm up to 2650and thickness range from 0.3mm up to 4.5mm. The envisaged total production for the line is about 100,000 tons/year with a process speed of 60m/min. The line is equipped with a double unwinding pay off reels and with a tailor-made stitcher with automatic spray lubrication system. The entry side trimmer is equipped with integrated scrap chopper. The alkali degreasing section is made by a spray tunnel with multistage cascade rinsing section. Entry and exit loopers are horizontal type with double winch motorisation. Chemical process starts with an acid tunnel etching section, followed by a no-rinse spray titanium zirconium passivation and a squeegee roll coater for oxylane product for automotive adhesive bonding application. The exit side includes a tension leveller, a pre-aging furnace, an automatic surface inspection system, a dry lube smelter and a rotary shear. The thermal portion is supplied by Ebner Industrieofenbau, one of the leading suppliers in floating furnaces for aluminium heat treatment processing line plant, consolidating the partnership between the two companies in aluminium lines and increasing their top record reference list worldwide. The line is expected to start its production at the beginning of 2021.