24/11/2020 – New wet grinding machine

“H120.1” completes the range of pendular grinders

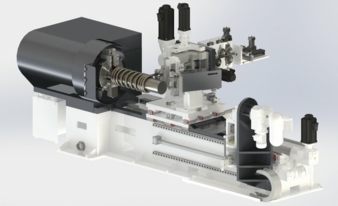

Also this year, despite the current pandemic, OMD has launched new products on the market. Regarding the sector of springs with medium-large wire diameter, a new coiling lathe type “WH36” has been added to the range of automatic cold winding machines for springs with wire diameter up to 36mm.

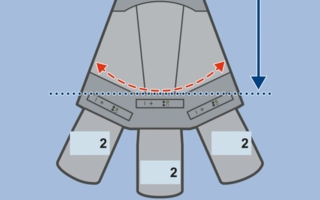

The new wet grinding machine “H120.1” completes the range of pendular grinders; the grinding wheel diameter is 1,200mm and it has been designed for grinding springs with wire diameter up to 70mm, with an outside diameter of 530mm and with a spring length of 1,300mm. The applied technical solutions concern: the adjustment of the inclination of the vices to correct the geometry of the springs, the easy positioning of the springs in the pendulum, the automatic grinding wheel dressing operation, the variation of the rotation speed of the grinding wheel, the automatic compensation of the grinding wheel wear, the system for grinding wheel change, the automatic opening / closing of the operator protection and a graphic programming that enables both a quick and easy management even for non-skilled operators and as well as the creation of special programs.

In support of the wide range of grinding machines OMD offers automatic loading systems to make the machine autonomous while minimising labor costs. The innovative and revolutionary “RLM” (Robotic Loading Machine) system has been designed for the automatic loading of the springs on the loading plate using an antropomorphic robot. The advantages of the RLM can be summarised as follows: versatile and flexible, high performance, reduced set-up times, possibility of loading both for grinding with continuously rotating loading plate as well as for step-by-step movement of the loading plate, graphic programming integrated in the software of the spring grinding machine.

Finally, also in the wire processing sector, the Multiformers series “TM” covering a complete range of wire diameter from 0.2mm up to 9mm and the looping machines series Z covering a complete range of wire diameter from 0.2mm up to 4.5mm, the constant development of electronics, of programming and tools ensure different technical possibilities for the realization of every type of bent part and an excellent flexibility while changing equipment with reduced machine setup times. Using these types of machines ensures a simple and linear working cycle and the result is excellent both from the point of view of the quality of the finished product as well as from the point of view of the production capacity.

The ability to innovate enables OMD Officina Meccanica Domaso SPA to define new product lines which can detect and anticipate market trends.

OMD Officina Meccanica Domaso S.p.A.

Via Case Sparse, 205

22013 Domaso (CO)/Italy

Tel.: +39 0344 97496

info@o-m-d.it

www.o-m-d.it