24/09/2025 – A conversation with Troy Libby, MAC Application Engineer

Expert insights on wire testing

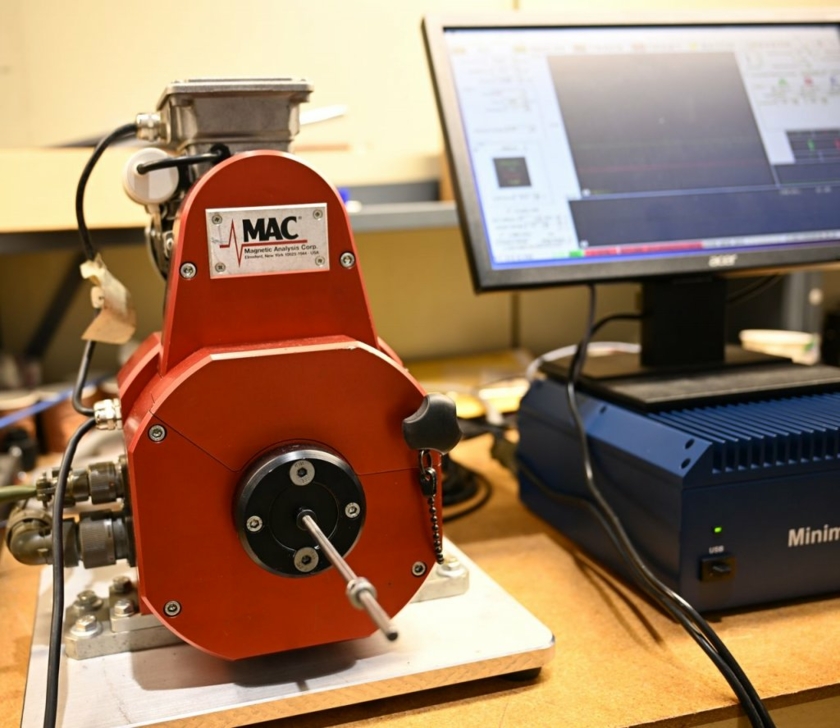

Troy Libby is a Senior Application Engineer in a design group at Magnetic Analysis Corporation. He has over 25 years experience in eddy current technology including designing inspection instruments, test coils and probes.

Eddy current testing offers fast, reliable, and non-contact detection of surface and near-surface defects in wire products – making it ideal for continuous production environments. © Magnetic Analysis

MAC has successfully provided systems capable of testing wire at speeds up to 5,000ft per minute. © Magnetic Analysis

Eddy current testing offers fast, reliable, and non-contact detection of surface and near-surface defects in wire products – making it ideal for continuous production environments. © Magnetic Analysis