20/09/2024 – “YJ-320” pushing the limits of cold coiling

Emerging for EV demand

The “YJ-320” spring machine pushes the boundaries of cold coiling technology, enabling the production of suspension springs with diameters up to 22mm and tensile strengths reaching 2,000MPa.

Under the overarching trends of net-zero emissions and energy efficiency, electric vehicles are gradually replacing gasoline vehicles. The batteries of electric vehicles are typically very heavy and occupy significant space at the vehicle’s bottom. This demands higher load-bearing capacity from the suspension system.

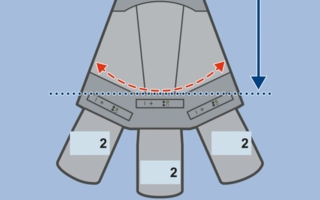

A good suspension system ensures ride comfort and safety, and the suspension spring plays an important role. The suspension spring primarily bears the vehicle's weight and provides flexibility to reduce the impact of vibrations and bumps, especially during sharp turns and on uneven road surfaces. A spring with a larger diameter and higher tensile strength provides better support for the additional load.

By further improving the cold coiling technology, The “YJ-320” can manufacture suspension springs with diameters up to 22mm and tensile strengths up to 2,000MPa. The mechanical design not only emphasizes strength but also integrates operability and safety. It is equipped with advanced Japanese Yaskawa servo control systems and patented editing software to meet the future demands of the EV market.

The cold coiling process offers significant benefits over traditional hot coiling, particularly in terms of energy efficiency, material properties, and environmental impact. With the capability to produce high-strength suspension springs and the integration of advanced control systems, “YJ-320” is well-positioned to meet the evolving demands of the EV market and contribute to more sustainable manufacturing practices.

Taiwan Simco Company

6F.-1, No.27, Ln. 61, Sec. 1, Guangfu Rd.,

Sanchong Dist., New Taipei City 24158/Taiwan

Tel.: +886 2 29954088

simco@simcotw.com

www.simcotw.com