26/03/2025 – New “All-in-One” machine produces up to M 20 bolts directly from the coiled wire

Cold and hot forming of bolts and screws

With the new “BM 12” bolt-making machine, Amba increases the range of products covered by its “All-in-One” series of machines to include wire gages of up to 18mm (~ 0.7“) diameter. It is the most powerful of all machines ever built by Amba and, due to the high upsetting forces involved, the first to use inductive heating for the forming of the bolt head.

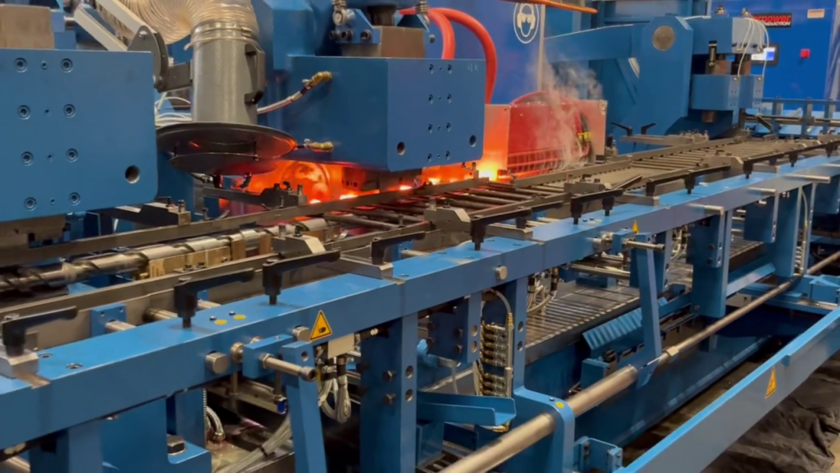

Fig. 1: Due to the high forming forces required, the bolt heads are inductively pre-heated before the upsetting process. © Amba

Fig. 3: At the induction stage, the heads of the bolt blanks are heated to more than 1,000°C (~ 1,850°F). © Amba