19/05/2023 – Advantages and disadvantages

Choosing the right welding system for battery packs

Tab-to-terminal connection is one of the key battery pack welding applications. Manufacturers need equipment, systems, and automated lines that meet quality and production requirements for these products. The critical process step for battery pack welding is joining the individual batteries together using a collector plate which consists of tabs for the individual cells to be welded to both the positive and negative terminals.

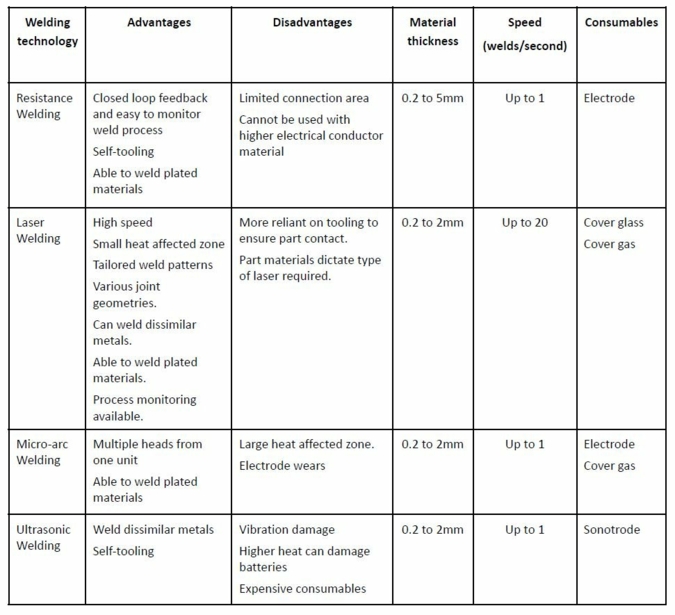

Table: Welding technologies for battery packs: an overview of the advantages and disadvantages. © Amada Weld Tech