04/04/2024 – The “FMU 100+”, for wire thicknesses up to 10mm, will make its debut at “wire”

A new addition to the successful “FMU+” series

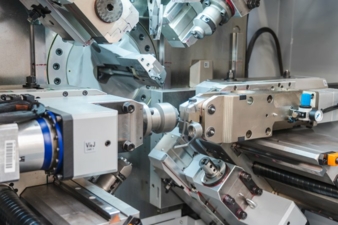

The “FMU+” series from Wafios is world-renowned for its flexible production technology for torsion, extension and extended loop springs. The new “FMU 100+” is capable of bending, winding and coiling wires with a diameter of 10mm, while the optional integrated Kuka robot facilitates component handling. The machine will make its debut at “wire” in Düsseldorf.

The “FMU 100+” can be used to process springs and bent parts in all kinds of industries, from agriculture and white goods to mechanical/plant engineering and the automotive sector. The torsion spring machine is part of the well-known “FMU+” series (from 0.2mm to 10mm) and is expanding the product line for customised production in the upper working range in response to high demand.

The “FMU 100+” allows for precise bending of high-strength spring steel wire in a diameter range of 4.1mm to 10mm. The versatility of this winding, coiling and bending machine is evident even in the basic version, which has nine highly dynamic, energy-efficient CNC axes. The modular machine setup allows for an expanded configuration with up to 24 CNC axes, thus fulfilling even the most demanding of production requirements. Almost any type of spring can be produced thanks to the wide range of available options.

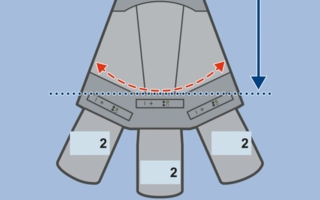

3D bending technology for new applications

The “FMU 100+” is particularly well suited to manufacturing torsion springs, extension springs and bent parts. It can, for example, be used to produce spring tines for agricultural equipment. The 3D CNC bending technology of the “FMU 100+” makes it easy to manufacture different workpiece geometries without having to change tools.

Thanks to the innovative tool solutions developed by our experts, the machine can be used to produce highly sophisticated geometries or special components. Furthermore, users are also able to use tools from other “FMU+” models on the “FMU 100+”.

The clearly structured input screen on the multi-touch monitor allows users to input geometry data, assign tools and carry out a feasibility check prior to starting production, and reduces the setup time for a new program.

Optimised spring production with intelligent simulation

The “iQspring+” program saves material and prevents collisions at the same time. A digital twin can be used to check and optimise the sequence before production starts. This means that collisions can be detected in the simulation – without breaking any tools or damaging the machine axes. In the event of a collision, the software automatically identifies alternative sequences and then outputs the maximum number of pieces for each variant. This allows the setup work for complex parts to be carried out quickly, and also reduces the amount of material required for setting up the process. The software automatically optimises unnecessary axis travels on the basis of the simulation, thus increasing the output rate during operation.

The energy efficiency system allows individual drives to be switched off if necessary. This means that, if assemblies such as rotary units are not required, the user can park them safely on the machine to save space.

Enhanced safety with the “FMU+” series: all servo motors are designed as “safe axes”. When protective devices are open, the machine retains the position of all axes even after being powered down. The reduced speed allows the operator to set up the program and process sequences during safe operation.

“Easy Robot” allows easy pick-and-place processes

“Easy Robot” is integrated into the machine control for even easier component handling, with the component program and the robot program being merged together. Integration into the Wafios programming system “WPS 3.2 Easy Way” eliminates the separate and extremely time-consuming setup process for the robot and means that operators do not require specific programming knowledge or training. All pick-and-place processes are implemented in one application to save time, and the robot axes can be moved conveniently using the machine’s hand-held operating device. In addition to the ready-to-operate robot, the “Easy Robot” scope of delivery also encompasses all of the equipment, including the base, energy supply, collision protection and parallel gripper. The CE-compliant design ensures safe production operation.

Live at “wire” and “Tube” in Düsseldorf

The “FMU 100+” all-rounder will be showcased at “wire” Düsseldorf together with the fully integrated “Easy Robot” from 15 to 19 April 2024. Come and visit them at stands F22 and F40 in hall 10. Visitors will also find Wafios AG at “Tube” in hall 5, stand A 21 / A 22.

wire 2024, hall 10 booth F 22 / F 40

Wafios AG

Silberburgstrasse 5

72764 Reutlingen, Germany

Tel.: +49 7121 146-0

sales@wafios.de

www.wafios.com

About Wafios

Wafios develops, designs and produces sophisticated, specialist machinery for the wire and tube processing industry and for cold-forging applications. The company is one of the world’s foremost providers in this field, with more than 130 years of experience attesting to its quality and innovation. The product range comprises more than 130 different machine types. Equipped with state-of-the-art software, artificial intelligence and IoT, Wafios machines optimise output rates and quality and improve the setup process. 60 per cent of Wafios’ customers work in the automotive and supplier industry, with a growing number in the field of e-mobility. The company also serves major industries such as mining, construction, electrical engineering, medical technology, household appliances, agriculture and furniture. Exports account for more than 60% of total sales. Today, Wafios has evolved into a group of companies that consists of parent company Wafios AG, based in Reutlingen, plus several locations throughout Germany (Reutlingen, Marktredwitz, Wuppertal, Berlin and Simonswald), France (Ecuelles), Portugal (Maia), the Americas (Branford, USA; Mokena, USA; Querétaro, Mexico and São Paulo, Brazil) and Asia (Shanghai, China and Zhangjiagang, China). With the “Connectavo” brand, Wafios is expanding its core business and developing cross-sector software solutions for maintenance in places such as hotels, municipalities and industry.