01/04/2024 – Re-arrangement of modules enables precise straightening

40 high-strength bicycle spokes per minute

The third generation of Amba’s All-in-One reducing machines further improves the straightness of single- and double-butted spokes – as used in electric and cargo bikes, for example. The new machines can produce up to 40 spokes per minute.

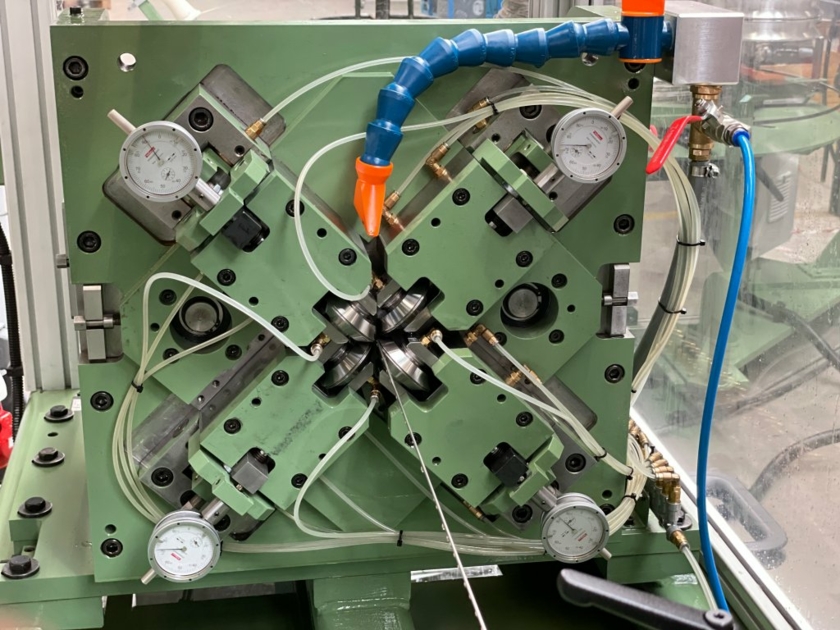

Servo-controlled actuators perform the radial movement of the two roll pairs positioned at 90° relative to one another. © Amba

The All-in-One DD 350-III reducing machines can produce up to 40 single- or double-butted spokes. © Amba

Servo-controlled actuators perform the radial movement of the two roll pairs positioned at 90° relative to one another. © Amba