01/04/2024 – Re-arrangement of modules enables precise straightening

40 high-strength bicycle spokes per minute

The third generation of Amba’s All-in-One reducing machines further improves the straightness of single- and double-butted spokes – as used in electric and cargo bikes, for example. The new machines can produce up to 40 spokes per minute.

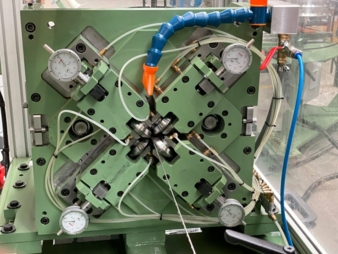

In the new machine generation, the rotary wire straightener has been re-arranged and is now positioned directly ahead of the cutter, behind the reducing section and the wire feeding unit. In this way, Amba avoids that transversal forces can act on the form-rolled wire during the feeding motion. Thus, the wire retains exactly the high level of straightness with which it leaves the straightener. At the same time, very tight roundness tolerances of just between two and three hundredths of a millimeter are attained.

According to Georg Haas, Sales Manager at Amba, the demand for this type of reducing machines has been rising lately: “The booming electric and cargo bike market has led to a growing demand for butted spokes. These are spokes that are thicker at one or both ends. Compared to non-motorized bicycles, spokes for these bikes are subjected to much higher loads because the bikes are ridden at higher speed and often used to transport heavy loads. Therefore, the spokes have to be able to cope with higher forces, especially during braking.”

Consequently, there has been increasing demand for single-butted spokes, i.e. spokes with a thick end at the hub and the usual diameter of 2mm at the rim. For wheel manufacturers these spokes provide the benefit that – while the spoke-hub connection becomes strong enough to accommodate the higher torque – they can still use rims of standard design. Double-butted spokes, i.e. spokes with two thick ends, are predominantly used in high-end bicycles. The advantage of these spokes is that they save weight and reduce windage.

Like all Amba products, the new DD 350-III gauge reducing machine is designed as an All-in-One machine. All production steps from paying-off the wire to the finished blanks are performed within a single machine. We are the only supplier to use servo-controlled form-rolling in our machines. This process provides the benefit that the roll gap can be adjusted during the passage of the wire. Thus, it is possible to roll different, specific diameters – wherever desired – along the entire wire length. Cutting the wire after rolling within a thick section produces double-butted spokes. Cutting it at the end of a thin section produces single-butted ones.

wire 2024, hall 16 booth H 58

Aachener Maschinenbau GmbH

Werner-von-Siemens-Strasse 17-19

52477 Alsdorf/Germany

Contact person is Georg Haas

Tel.: +49 2404 551289-64

georg.haas@amba.de

www.amba.de

About Amba

Aachener Maschinenbau GmbH – generally referred to as “Amba” – was founded in 1908, at a time when Aachen was worldwide famous for its high-quality needle production. Since then, the company has evolved into an internationally renowned manufacturer of machinery used to make cold-formed metal components. Today, Amba specialises in equipment for the production of long and slender components with varying cross-sections, such as screws between 60mm and 2,500mm long, and tubes and spokes. The Amba All-in-One design has made the company the world’s only supplier of machinery that can perform all steps needed to manufacture long and complex components continuously on just one machine. All process steps from feeding the input stock – wire rod or tube blanks – up to the finished, packaged product are handled by just one machine. This is unique in the industry. At its headquarters in Alsdorf near Aachen, Amba employs 80 people in its development and design departments, in the workshops and in after-sales.