07/06/2021 – wire Russia 2021

Sustainable manufacturing solutions

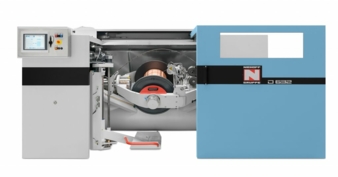

Niehoff and Niehoff of Russia (NoR), its Moscow-based sales and service branch, are well prepared to be present at the “wire Russia” 2021 trade fair on booth hall 3-B40. They plan to exhibit a double twist bunching machine type “D 632”.

Energy and material-efficient production

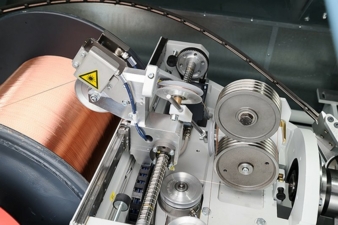

Niehoff has been attaching great importance to building machines that enable energy, material and cost-efficient production processes for a long time. One example for these efforts is the “D 632” on display. Typical features are the single-bow design with the Eco-Bow energy saving bow, the automatic traverse system “NBAT” and an adjustable and controlled wire tension, regardless of the spool filling. Each spool is filled with a perfect winding pattern.

Ideal for copper alloy fine wires

The D 632 is ideally suited for processing copper alloy fine wires such as CuSn0.3 or CuMg0.2 into strands. Using the “Stretch Forming and Straightening technology”, the machine avoids the crowning and spiraling effect typical for copper alloy wires.

Cost savings

An important criterion of the machine is that it helps reduce operational costs. Additional costs can be saved if the machine produces strands with very tight tolerances. This means that only the minimally required copper cross-section is generated – not more! Even more savings of energy costs result from the reduced power consumption of a D 632 equipped with an Eco-Bow. The NBAT system and the precise function of the machine enable a worker to operate more machines simultaneously, thus saving even more costs: For spooling a copper alloy strand with a cross section of 0.13 mm² on a 630 mm spool, e.g., the runtime of the machine is four days. The process is carried out automatically and requires no intervention of an operator. The result is a perfect winding.

Documented quality

For process monitoring, the machine can document parameters such as winding tension, lay length and number of twists, so that the user of a D 632 can prove top product quality in writing to his customer. From the beginning of April 2021 onwards, this machine like all new Niehoff machines to be delivered to Europe is equipped with the Niehoff Digital Assistant+ Basic module.

Technical data D 632

Max. production speed: 300m/min

Production range

Strand cross-section (soft Cu): 0.09mm² … 6.00mm²

Lay length (steplessly variable): 6mm … 100mm

Max. number of twists: 7,000twists/min

Maschinenfabrik Niehoff GmbH+Co. KG

wire Russia 2021, booth 03/B40

Walter-Niehoff-Strasse 2, 91126 Schwabach/Germany

Tel.: +49 9122 977-0

info@niehoff.de

Branch of Maschinenfabrik Niehoff GmbH+Co. KG

in the Russian Federation

Storogevaya Street 4, house 1

Moscow, 111020, Russian Federation

Tel.: +7 499 929 5537, 5538

Fax +7 499 929 5539

info@niehoff.de

Niehoff’s experience in the Russian market started more than 30 years ago with first connections to Russian cable manufacturers. Niehoff of Russia (NoR), their sales and service branch in Moscow, was set up in 2005 and is responsible for all Niehoff activities in the Russian Federation and neighbour countries. NoR's six service engineers, all Russian native speakers, install Niehoff machines at customer sites, put the machinery into operation and provide after sales service. Since 2008, Niehoff and NoR have been working closely together with the All-Russian Scientific Research and Development Cable Institute VNIIKP.

Complete solutions from a single source

With an experience of 70 years in the wire and cable industry, Maschinenfabrik Niehoff develops and builds machinery needed for the production of non-ferrous wires and their downstream processing into automotive, power, data and special cables – the only exception are extruders. Additionally, the company provides technical assistance by experts speaking the customers´ languages, and reliable supply of OEM wear and spare parts. Professional machinery inspections, competent maintenance, refurbishment and upgrading measures as well as machine operator and maintenance training courses imparting sound knowledge, are also part of the available services. Remote commissioning and relocations of Niehoff machinery on the customer’s site complete the wide range of Niehoff services.

Niehoff Group offers custom-tailored solutions from development and planning to turnkey projects of complete cable factories. Understanding the signs of the times, Niehoff faces the daily challenge in development and production to minimise the consumption of resources and to contribute to the protection of the environment. As a matter of course, Niehoff delivers products that help their customers to reduce energy consumption. In this context, it was a logical conclusion to join the “Blue Competence” sustainability initiative of the German Engineering Federation VDMA and, simultaneously, to commit to complying with the twelve Sustainability Guidelines of the Mechanical Engineering Industry (www.bluecompetence.net).

Niehoff Group with more than 850 employees worldwide is comprised of the headquarters, six manufacturing subsidiaries (in Brazil, the USA, the Czech Republic, India, China, and Sweden) as well as sales and service centers in Japan, Singapore and Russia.