09/05/2025 – Nondestructive testing (NDT) equipment and systems

Innovative inspection solutions

Magnetic Analysis Corp. (MAC), a longtime provider for nondestructive testing (NDT) equipment and systems, will be exhibiting its inspection solutions.

Visitors to MAC’s booth #553 will have the opportunity to see live demonstrations of some of the company’s most advanced inspection equipment, including the “Minimac II”, “Rotomac 25mm RM”, and MAC’s “Quality Grading Software”.

The “Minimac II”, popular with wire manufacturers for its ability to detect short surface and some subsurface defects in wire, rod, and tube at speeds up to 4,000f.p.m., will be featured in live demonstrations at MAC’s booth. Attendees will witness the “Minimac II” in action, including a linear rail fixture that will demonstrate its capabilities for inspecting small diameter wire.

This system is commonly used for inspecting welding wire, including flux core wire, where it can detect missing flux and flaws in the wire. The “Minimac II” also excels at checking continuity and detecting welds in single and multi-conductor insulated wire and cable. With its MID option, the Minimac II is effective in detecting magnetic inclusions in non-magnetic products, making it an invaluable tool for various industries.

In addition to the “Minimac II”, MAC will also have the “Rotomac 25mm” rotary on display, which offers a cost-effective and reliable solution for inspecting wire or rod for cracks and seams. Operating at 1,000rpm, the “Rotomac 25mm” features air ride probes, a single test channel, and easily accessible test probe adjustments. It can handle wire diameters ranging from 1/8” to 1” (3mm – 25mm) and is capable of throughput speeds ranging from 12ft./min to 40ft./min. The rotary’s highly accurate distance compensation, when using an absolute probe, ensures precise testing, even for excessively out-of-round products. It operates on 120 VAC with no special control box or utility requirements, making it an easy addition to any production line.

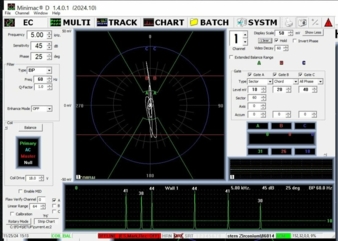

MAC will also demonstrate its powerful “Quality Grading Software”. This software offers real-time solutions for automatically categorizing the quality of rod, wire, and coil segments during production, ensuring precise defect detection and efficient quality control.

Compatible with both the “Multimac” and “Minimac II” eddy current testers, the “Quality Grading Software” allows users to customize defect types, set thresholds, and define grade levels based on surface defects and inclusions. It also tracks defects by type, counts them in separate counters, and generates detailed reports that include coil IDs, grades, and defect counts. These reports can be exported in CSV format for easy integration with customer databases, and multilingual support is available. The software also provides options to automatically print coil labels and manually generate reports for specific data, enhancing production tracking.

MAC’s Engineering Manager, Troy Libby, along with several members of the Sales Team, will be available at the booth to answer any questions and discuss how MAC’s NDT testing solutions can benefit your facility. Attendees will also have the opportunity to learn more about MAC’s complete range of eddy current, conventional and phased array ultrasonic, and flux leakage test systems for wire, tube, and bar.

Interwire 2025, booth 553

Magnetic Analysis Corporation

103 Fairview Park Drive, Suite 2

Elmsford, New York 10523-1544

Contact person is Andie Nichols

Tel.: +1 914 530-0015

anichols@mac-ndt.com

About Magnetic Analysis Corp.

Founded in 1928, Magnetic Analysis Corp. (MAC) is a leading provider of nondestructive testing equipment and systems. With a history of innovation and commitment to quality, MAC designs and manufactures eddy current, ultrasonic, and flux leakage test systems for wire, tube, bar, and other materials. MAC’s products are trusted by industries worldwide for their accuracy, reliability, and effectiveness in ensuring product integrity.