15/10/2020 – wire 2020 update

Continuous inkjet printing solution for pre- and post-treatment extrusion lines

Domino Germany informs us that the company has regretfully cancelled its participation in the "wire".

Domino Printing Sciences (Domino), an expert in coding, marking and labelling solutions, will return to Dusseldorf this year for “wire” 2020. Join the company for a first-hand look at its innovative solutions for printing on cable and wire, including single-source supply of fully integrated plasma pre-treatment, coding and UV post-treatment. Coding experts from the cable and wire sector will offer their practical expertise and demonstrate Domino’s wide range of specialised inks.

Domino offers coding and marking solutions for printing fixed and variable data, including 1D and 2D codes, symbols, logos, batch and charge numbers, metre and inch markings, version and type designations, and test numbers. Solutions and inks are available for printing on a wide range of substrates including PE, PU, PVC, Teflon, silicone, metal, and halogen-free material.

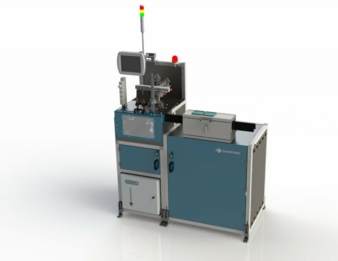

This configurable solution features Domino’s “Ax350i” continuous inkjet (CIJ) printer, fully integrated with plasma pre-treatment and UV post-treatment in a single solution, ensuring optimum print adhesion to the product.

The modular, easy to configure solution is ideally suited to process uncut and round products such as cables of all types, pipes, tubes, and profiles with a diameter of 0.8mm to 50mm, at speeds of up to 300m/min. The system also features hardware protection against knots with a diameter up to 50mm.

Domino’s new innovative laser enclosure offers a CO2 or fibre laser solution with a product guiding and length measurement system ensuring the achievement of Laser Class 1 safety standards for the production line.

This innovative solution offers a variety of specification possibilities (particularly for fibre laser systems) enabling coding onto a wide variety of products, such as cables, wires, tubes and hoses.

While the product guiding system makes height adjustments for different product diameters a thing of the past, it also allows for the processing of knots with a diameter up to 50mm at speeds of up to 300m/min.

The laser enclosure can also be easily integrated into existing production lines and has the added benefit of hard-wearing parts that do not require maintenance.

Domino Germany GmbH

wire 2020, no participation in this year

Tel.: +49 6134 250651

www.domino-deutschland.de