08/12/2023 – Cooperation Agreement between Tenova and GE Vernova

Tailored medium voltage power feeding solutions for large EAFs

Steelmakers are increasingly looking for technological solutions to transform their existing Ironmaking lines and reduce their carbon footprint.

Tenova, a global company specialized in sustainable solutions for the green transition of the metals industry, and Power Conversion – a GE Vernova business –, a leading company in supplying advanced electrical systems and services for a wide range of industries, signed a Cooperation Agreement to join efforts and work together on target projects to offer and implement innovative power feeding solutions based on medium voltage power converters for Electric Arc Furnace (EAF) or Submerged Arc Furnace (SAF) technologies.

This leads to a growing demand for very large, highly productive electric furnaces that poses substantial challenges to the stability of the energy distribution grids, and all too often the active power needed to meet the productivity targets of the users is not reachable with conventional energy supply schemes.

To meet the needs of the future, Tenova and Power Conversion have formed this collaboration to jointly design and market tailored medium voltage power feeding systems for EAFs and SAFs allowing the effective use of high electric power even on constrained grids and reducing both operating costs and environmental impact of new and pre-existing furnaces.

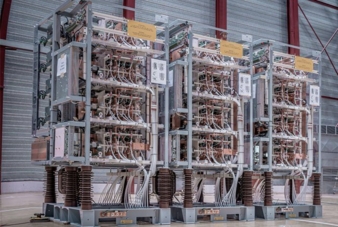

GE Vernova’s Power Conversion business has developed an advanced power supply solution, called Direct Feed, dedicated to Electrical Arc Furnaces. This innovative AC-DC-AC solution based on scalable patented back-to-back hybrid Modular Multilevel Converter topology is directly connected to the grid (up to 60kV).

Modular Multilevel ConverterGE’s Direct Feed system controls accurately the EAF voltage and arc current/power at variable frequency. Its digital control system enables a qualitative monitoring of the electrical arc offering improved process stability, better OpEx and enhanced grid power quality performance. It is addressing the more and more challenging constraints imposed by grid codes which conventional solutions cannot meet.

“With this new collaboration, two companies sharing a common culture of transparency in business and passion for technology join forces to meet the ever-increasing expectations of a market in tumultuous development and bring the steelmaking industry one step further towards decarbonization.” comments Paolo Argenta, Tenova EVP of the Upstream Business Unit. “The vast experience of our Companies in the respective technical fields, together with the expertise of our end users, allows us to bring to the market an effective, flexible, reliable solution to EAF and SAF operators.”

Edgardo Torres, Power Conversion’s Chief Operations Officer, said: “I’m looking forward to starting this collaboration with Tenova. Being trusted by such an important player of the steel market confirms that our Direct Feed technology is the right answer to the growing challenges faced by the industrials. We propose an innovative solution to the steel makers, that will not only allow them to increase their performances but also support them on their decarbonization journey while providing a much better OpEx.”

www.tenova.com | www.gepowerconversion.com