17/10/2023 – 3-roll Reducing+Sizing Block for Chinese Xinji Aosen Steel Group

New order for Kocks “RSB” from China

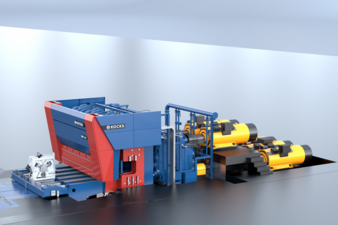

The Chinese steel producer Xinji Aosen Steel Group Co. Ltd. and Friedrich Kocks GmbH+Co. KG have signed a contract for the installation of an “RSB 370++/4” Reducing+Sizing Block in 5.0 design. The block is regarded as the pivotal element of the company's greenfield rolling mill for SBQ products.

The private Xinji Aosen Steel Group was established in 2002. The company is engaged in iron and steel smelting, steel processing, the production of building materials, and international trade. With a workforce exceeding 8,000 employees, Xinji Aosen currently boasts an annual production capacity of 5.05 million metric tons in various product categories, including billets, wire rod steel, construction steel, high-quality carbon construction steel, welding and high-speed steel wire, as well as galvanised wire.

The now made investment in a state-of-the-art 700,000 metric tons per annum Special Bar Quality (SBQ) rolling mill is a significant milestone for Xinji Aosen, marking its entry into SBQ straight bar production for the first time. Positioned after 21 H/V-stands, the Kocks Reducing+Sizing Block will finish bars onto the cooling bed within a dimension of diameter 20.00mm to 90.00mm with the highest dimensional tolerance.

The scope of supply further includes the remote control for stand and guide adjustments, the equipment for the roll shop, and the further advanced “Bamicon” Octopus software that assists operators in the stand and guide preparation and supports the entire tooling process. The commissioning of the “RSB” is scheduled for the end of 2024.

About Kocks

The Kocks Group, headquartered in Germany, is a global supplier of rolling mill equipment for sizing applications. Founded in 1946, Kocks has become a globally recognised brand. The Kocks 3-roll technology has gained the company a reputation as an innovator. The core competencies include consulting, planning, development, design, supply, assembly and commissioning of rolling mills and automation solutions as well as modification and modernisation of existing rolling mills.