23/09/2024 – SSAB and Trelleborg in collaboration

Fossil-free steel for brake pad shims

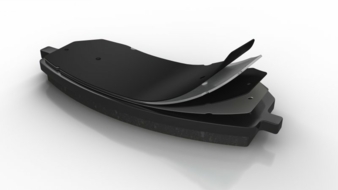

SSAB has reached an agreement with Trelleborg Sealing Solutions Kalmar AB to deliver fossil-free steel to be used in anti-squeal plates, so-called shims for brake pads. Shims are an important part used for eliminating brake noise, especially in electric cars where annoying sounds are heard more clearly.

Demand for sustainable components is high among vehicle manufacturers. This is especially true in the growing electric car segment, where the materials in the car account for a large part of the remaining carbon dioxide emissions after the exhaust gases have been eliminated. Therefore, Trelleborg Sealing Solutions Kalmar AB, a leading manufacturer of sound damping shims, wants to offer brake shims with a significantly lower carbon footprint than standard. This agreement with SSAB on future deliveries of fossil-free steel is an important part of that goal.

“Our unique solutions to eliminate vibration and noise in cars are based on our technical knowledge and experience. With fossil-free steel in our components, we will take a leap forward and strengthen our market-leading position,” says Stefan Lundström, Business Unit President, Trelleborg Sealing Solutions Kalmar AB.

"We are happy to welcome Trelleborg Sealing Solutions as a fossil-free partner. Together, we will support the automotive industry in delivering the key parts that both producers and consumers are demanding. In the end, it will deliver more sustainable cars to the customers,” says Olavi Huhtala, Head of SSAB Europe.

Traditional steel production represents a significant source of global CO2 emissions. By changing the way steel is produced, SSAB wants to cut emissions and create a fossil-free value chain with customers and partners.

SSAB has developed two unique types of steel that are produced with virtually no fossil carbon dioxide emissions: “SSAB Zero” and “SSAB Fossil-free” steel. “SSAB Zero” is based on recycled steel scrap and is produced with fossil-free electricity and biogas and is available for commercial deliveries since 2023. “SSAB Fossil-free” steel is produced from iron ore with “Hybrit” technology developed by SSAB together with iron ore producer LKAB and energy company Vattenfall. The technology, which has been tested on a pilot scale, uses hydrogen produced with fossil-free electricity to produce iron, the primary raw material in steelmaking. The residual product is water instead of carbon dioxide.

About Trelleborg

Trelleborg Sealing Solutions Kalmar AB has been supplying damping solutions such as brake shims since 1988. The company's products are used by virtually all major vehicle manufacturers in the world to reduce annoying noise and vibrations during braking, for example. Shims are manufactured by combining different materials, mainly rubber and metal, and are attached to the brake pads.

About SSAB

SSAB is a Nordic and US-based steel company that builds a stronger, lighter and more sustainable world through value added steel products and services. Working with our partners, SSAB has developed “SSAB Fossil-free” steel and plans to reinvent the value chain from the mine to the end customer, largely eliminating carbon dioxide emissions from our own operations. “SSAB Zero”, a largely carbon emission-free steel based on recycled steel, further strengthens SSAB’s leadership position and our comprehensive, sustainable offering independent of the raw material. SSAB has employees in over 50 countries and production facilities in Sweden, Finland and the US.