20.03.25 – b&m-EccoTec

A forming vision with disruptive potential

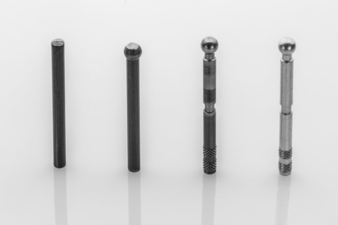

Screw and fastener specialist Baier & Michels (b&m) has developed a chipless manufacturing process for long turned parts that previously could only be produced with machining methods using multiple process steps.

“The advantages of the b&m-EccoTec process developed by us are: short cycle times and complete utilization of the raw material used combined with absolute contour freedom and excellent quality of the strain-hardened surface.” Olaf Ambros, Head of Technics and R&D at b&m. © b&m/Sabina Hagedorn

The forming technology is a non-cutting manufacturing processes with constant volume. © b&m/Rüdiger Dunker

“The advantages of the b&m-EccoTec process developed by us are: short cycle times and complete utilization of the raw material used combined with absolute contour freedom and excellent quality of the strain-hardened surface.” Olaf Ambros, Head of Technics and R&D at b&m. © b&m/Sabina Hagedorn