12/11/2020 – Smart machine maintenance

New AI system also detects unknown faults

A new maintenance system is helping to make sensors smart. A research team led by Professor Andreas Schütze of Saarland University is combining artificial intelligence with sensors that gather status data on industrial machinery.

“A single sensor can generate a terabyte of raw data in just a few days,” explains Professor Andreas Schütze, an expert in measurement and sensor technology at Saarland University. © Oliver Dietze

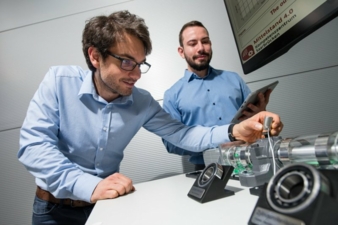

Steffen Klein (l.) and Christopher Schnur, research assistants in the group led by Andreas Schütze, are currently conducting research into the new system. © Oliver Dietze

Christopher Schnur (l.) and Tizian Schneider, research assistants in the group led by Andreas Schütze, are currently conducting research into the new system. © Oliver Dietze