16/10/2023 – Reutlingen E-Mobility Days on October 17-19, 2023

Wafios welcomes e-mobility experts

The Reutlingen E-Mobility Days (RED) take place for the fourth time on October 17-19, 2023. In only a few years, the event staged by Wafios has become well established among e-mobility designers and experts. Technologies and manufacturing solutions are presented without which modern e-drives are no longer conceivable.

As in the past year, Wafios' cooperation partner Gehring Technologies GmbH+Co. KG will once again be an exhibitor at the show. Also, numerous co-exhibitors from research and production will present their work. Thus a whole bunch of new inventions for even more powerful e-drives will be waiting for visitors. “We are delighted to see that our E-Mobility Days attract so much interest, the event is continuously growing”, explains Dr.-Ing. Uwe-Peter Weigmann, CEO of Wafios AG. “This year, we are expecting even more visitors than last year. Therefore, we soon knew: we will provide even more space for the REDs in 2023 than we did in the previous years and we will invite even more co-exhibitors.”

The following co-exhibitors have already confirmed their participation: the manufacturer of contactless 3D measuring systems Hexagon-Aicon, the copper wire supplier HPW, the casting expert Lambda Resins, the manufacturer of straightening devices Witels-Albert, the manufacturer of batteries Elring Klinger, the Karlsruhe Institute of Technology (Institute of Production Science wbk), and the RWTH Aachen (Production Engineering of E-Mobility Components, PEM). This year's REDs will focus on the following four topics:

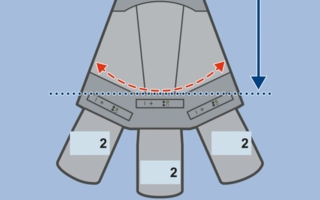

Hairpin bending technology “HQ Bending”

The new Wafios hairpin bending technology “HQ Bending” enables the bending of hairpins with a very flat geometry of the hairpin head/crown. Thus there is less room needed for installing the hairpins so stators can be built even more compact. The new technology uses a special rotary unit and a newly developed tool concept for producing the hairpin crown/head. There are no disadvantages as compared to the production with presses. The patent application for the new technology has already been initiated, and three further patents are in preparation.

The production of hairpins based on the latest technologies will be demonstrated to visitors. To this end, there will be two machines available: The first one is a hairpin machine of the “FMU E” series, a universal production system not only for hairpins but also for stator connection assemblies and inductor coils for axial flux motors. The second one is the “Speed Former” transfer bending machine with a dual-coil pay-off unit and parallel rod transfer. With this machine Wafios shows how large batches of hairpins can be produced.

“FMU 40 E”

Another machine exhibited by Wafios is the “FMU 40 E”, which has been developed for the production of axial flux coils that are installed in high-performance drives. This is an application example from premium vehicle construction: The coils are used, e.g. in the e-drive of the super sports car Gemera from the Swedish manufacturer Koenigsegg. “We have developed a new bending concept for this application. This makes us currently the only machine manufacturer in the world that can economically produce these coils in the required quality”, emphasizes Dr. Uwe-Peter Weigmann. The coils can be picked up from the machine automatically by means of the Wafios “Easy Robot” software or other customized solutions. The advantage of “Easy Robot”: The software integrates the handling robot into the machine's control system. Thus the robot can be operated easily. The first “FMU 40 E” made for this application will be delivered already in 2023.

New developments for the production of busbars

There are also new developments for the production of busbars which are required e.g. for loading the batteries in electric vehicles. These components can be produced with the Wafios “BMF 60” and now also with the even larger “BMF 90”. The “BMF 90” will be available for presentations at the REDs. It has been developed to meet the trend towards larger cross sections that shall enable shorter battery loading times. As a result, the current levels are increased so that the heat generation is decreased. For weight reasons, vehicle manufacturers are also increasingly opting for busbars made of aluminum, a material which the “BMF 90” is able to process with cross sections of up to 50mm x 4mm. A unique bending tool concept with a release stroke for best bending results and a fully integrated mechanical or laser-based insulation stripping device for removing the insulation layer at the connecting ends, are more unique selling points. The mechanical insulation stripping device is a new development for removing the insulation from busbars. It is equipped with seven axes that offer high flexibility with regard to cross sections while cycle times can be reduced by up to 40%.

In-process measurement of stators

Gehring too focuses on innovative technologies. They will exhibit their latest developments for the in-process measurement of stators before and after certain assembly steps. Laser triangulation is used for measuring. Another highlight will be the exclusive preview on Gehring's latest generation of hairpin assembly lines. Their innovative concept includes two extremely fast Scara robots that promise an even more efficient assembly process. The continuous enhancement of these hairpin assembly lines demonstrates the company's commitment to forward-looking solutions.

Aside from the above topics, the REDs also offer the opportunity to discuss the most diverse questions and aspects related to e-mobility, either at the booths of our co-exhibitors or during the lectures held by various experts from science and industry. Konstantin Neiss from Mercedes Benz, for example, will deliver a keynote presentation on powertrains. Last but not least, an evening event on October 19 will top off the exhibition.

Wafios AG

Silberburgstrasse 5

72764 Reutlingen/Germany

Contact person is Haiko Raßweiler

Tel.: +49 7121 146-0

sales@wafios.de

www.wafios.com

About Wafios

Wafios develops, designs, and produces sophisticated, specialist machinery for the wire and tube processing industry and for cold-forging applications. The company is one of the world’s foremost providers in this field and offers more than 130 different machine types. Its machinery is equipped with state-of-the-art drive and control technology as well as innovative software. 60% of Wafios' customers work in the automotive and supplier industry. But the company also serves major industries such as mining, construction, electrical engineering, medical technology, household appliances, agriculture, and furniture. Exports account for more than 60% of total sales. Today, Wafios has evolved into a group of companies that consists of parent company Wafios AG, based in Reutlingen, plus several locations throughout Germany (Reutlingen, Marktredwitz, Wuppertal, Berlin, Simonswald, Hilchenbach), France (Ecuelles), the Americas (Branford/USA, Mokena/USA, Querétaro/Mexico; and São Paulo/Brazil), and Asia (Shanghai/China and Zhangjiagang/China).