10/01/2020

Twist-free and straight wire over decades

Lämneå Bruk is a family-owned, long-standing manufacturer of wire machinery with a proven track-record of more than 100 years’ experience in the industry. One of the bestselling machines, the “No Twist Coiler”, has been constantly improved and reinvented for twist-free and straight wire.

In 1992, the Swedish company Lämneå Bruk launched its first groundbreaking wire coiling machine, the “No Twist Coiler” (NTC). This highly flexible and adaptable machine enables fast and precise wire coiling at up to 40m per second. It is user-friendly with an up-to-date PLC control system and eye-level display. It can be used for a wide variety of different wire types ranging from solid, staple, fluxcore to even spring wire. To add to its high flexibility, the NTC is suitable for drums of different shapes and sizes, depending on the individual customer’s needs. And since the company is Swedish, they also aim for machines with low environmental footprint.

Re-think your wire production

At “wire” 2018, Lämneå Bruk presented its innovation: The No Twist Coiler (NTC) for spring wire. This advanced machine sets a new standard of bedding and seating wire coiling and offers an advanced solution for spring wire coiling. The NTC reverses the pre-twist and the wire comes out twist-free and straight. The machine offers the big advantage that no further straighteners are needed in the process. With no driven payout and no straighteners, the line is much more compact. It can be used in-line with the drawing machine or as a separate rewinding operation. Apart from that the NTC for Spring Wire uses less resources since no power is needed for the pay off. The results are more than convincing: Springs of consistent and even quality at the highest standard while the wire consumption per spring can be reduced at the same time.

Highest European safety standards

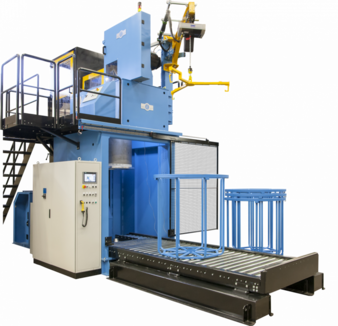

Last year the success story of the NTC was continued and crowned with the launch of the “No Twist Coiler 1200”. This machine is truly revolutionizing the wire industry. Not many other appliances allow to streamline the wire production process as the NTC 1200 does. This state-of-the-art machine can be used off-line but more effectively in-line with the drawing machine. The NTC 1200 acts as take-up for the drawing machine, while the inverted carrier is used as pay-off in the next production step and placed directly onto the floor. One of the major advantages is the handling of the package as undriven pay-off, resulting in twist-free and straight wire. Apart from that, this machine is truly an energy saver, streamlines the production process and has significantly lower downtimes due to the continuous production abilities. The NTC Solution Concept enhances the wire production and can even handle fine wires, packages of different sizes and saves costs and space.

Quality Made in Sweden

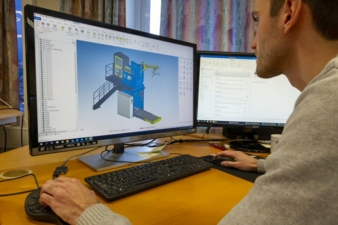

All machines are manufactured and planned on-site in the workshop in Sweden, from the first draft over producing the separate machine parts to the final assembly and programming. Lämneå Bruk has the full control over the production process which allows for highest flexibility and customization. Whatever requirements and wishes the customers have, Lämneå Bruk has the solution and can accommodate to (almost) all production needs. Since customer safety is one of their major concerns, all machines are CE marked and undergo a, thorough, three-step safety and risk analysis, exceeding European safety standards.

wire 2020, hall 9 booth A 06

Lämneå Bruk AB

61273 Ljusfallshammar/Sweden

Contact person is Ann Kathrin Hassenburs

Tel.: +46 122 23200