21/02/2021 – Automation /materials management

Traditional company prepares for the future

How Zeller+Gmelin achieves a sustainable increase in productivity through comprehensive automation measures in the field of materials management.

“The major skill required by our planning is to come to terms with the existing restrictions. Our approach is therefore to make maximum use of the existing buildings in order to modernise and expand our production in this way.” Ilija Lucic, project assistant of the technology management at Zeller+Gmelin. © Zeller+Gmelin

“The major skill required by our planning is to come to terms with the existing restrictions. Our approach is therefore to make maximum use of the existing buildings in order to modernise and expand our production in this way.” Ilija Lucic, project assistant of the technology management at Zeller+Gmelin. © Zeller+Gmelin

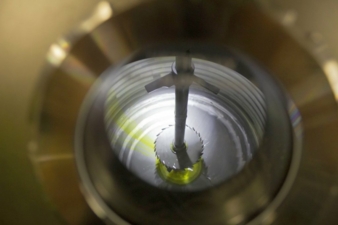

Several new storage tanks are to be installed on the factory premises by October 2019. Various engine, chain, hydraulic and formwork oils are stored in the tanks, which are then tailored on fully automatic filling lines. © Zeller+Gmelin

The process control at the vessels is fully automatic. The employee can conveniently control vessel cooling via a touch panel on the PC. Sensors provide precise information about the actual state of the greases in the vessel. © Zeller+Gmelin