18/04/2025 – Surface treatment / grinding

The future of feeding systems in spring grinding

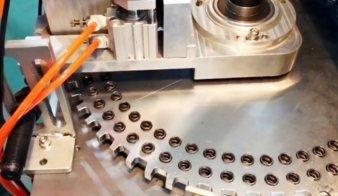

Simco’s automated feeding system for spring grinders is equipped with sensors and controls, effectively reducing spring tangling and improving loading accuracy.

In today’s manufacturing industry, automation is no longer a luxury; it has become necessary. The demand for automated solutions continues to surge, and the spring grinding sector is no exception, with automated feeding systems driving transformation in production processes.

Problems that can be solved through automation in spring grinding include:

1. Labor shortages:

Finding skilled workers for repetitive and physically demanding tasks has become increasingly difficult. Automated feeding systems provide a reliable solution.

2. Productivity demands:

Modern manufacturing demands faster production cycles and consistent quality. Manual feeding often struggles to keep up with these expectations, leading to inefficiencies and quality variations.

3. Safety concerns:

In the past, spring grinding relied heavily on manual feeding, requiring operators to manage material loading throughout the process bringing potential risks. Automation reduces these risks, creating safer workplaces.

Today, automated feeding systems have replaced these traditional methods, offering unmatched advantages:

1. Consistent Precision: Automated systems ensure precise and uniform material feeding, which enhances grinding accuracy and reduces material waste.

2. Uninterrupted Operation: Continuous feeding capabilities enable machines to run longer without manual intervention, boosting productivity.

3. Cost Efficiency: While the initial investment in automation may seem high, it quickly pays off by reducing labor costs, improving efficiency, and minimizing downtime.

Automated feeding system for spring grinding

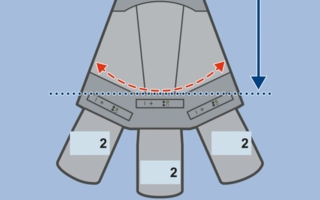

Simco's automated feeding system is equipped with sensors and controls. It uses a vibration device to feed springs and align them in a surrounding tray. The system supports up to four feeding paths and allows easy mold switching for similar-sized springs. When springs tangle, the system's eccentricity disperser effectively untangles them.

Automation is shaping the future of manufacturing

Automated feeding is not just about convenience; it is about staying competitive. They represent the next phase of industrial evolution. As businesses strive to overcome labor shortages and achieve higher production standards, automation offers a clear path forward. Whether you are upgrading your existing systems or investing in new technology, the time to automate is now.

Taiwan Simco Company

6F.-1, No.27, Ln. 61, Sec. 1, Guangfu Rd.

Sanchong Dist., New Taipei City 24158/Taiwan

Tel.: +886 2 29954088

simco@simcotw.com

www.simcotw.com