01/03/2021 – Shot blasting plant for metal wire

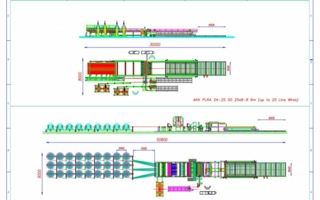

Shot blasting machine installed by Marcegaglia

Pangborn received an order from Marcegaglia to supply a shot blasting plant for metal wire. The plant was intended for the Marcegaglia Specialties plant in Contino (Italy), one of the 28 of the Marcegaglia Group, dedicated to the production of carbon and stainless steel drawn bars.

Drawn bars are widely used in the automobile and industrial vehicle industries, including earthmoving machinery and lifting equipment. Marcegaglia needed to replace an existing shot blasting machine with a more powerful and flexible one, capable of providing outstanding performance in terms of final cleaning of the bars, production capacity, efficiency and repeatability of results. The purpose of the shot blasting machine, placed in line in a coil-to-bar plant, is the descaling of the metal wire, before the subsequent drawing phase.

After a series of technical meetings with the Customer’s Project Manager, ing. Andrea Ceresetti, the Engineering activities aimed at defining the layout and customizing the system according to the specific needs of the customer.

In particular, in addition to the need to guarantee the required performance, great attention was paid to the flexibility of the system according to the various conditions of use.

The rapid development of the project was made possible by the collaboration between the technical offices of Pangborn Italy (Milan) and Pangborn Germany (Hagen), given the great experience of the latter for this application.

After the engineering phase, the plant was built in the Pangborn Italy plant and installed in January 2020.

The plant consists of two continuous shot blasting modules with independent abrasive circulation systems. Each module is equipped with three latest generation “Genesis” turbines, coupled to 45kW electric motors.

Each turbine is controlled by an inverter, capable of adjusting the rotation speed of the turbine and therefore the output speed of the abrasive, while the flow rate can be adjusted by means of special magnetic valves.

The possibility of adjusting the abrasive speed and the flow rate at the same time is of fundamental importance to maintain the point of use of the turbine on the maximum efficiency curve. At the same time, it is possible to avoid problems of under- or over-blasting, excessive abrasive consumption and excessive wear of components.

The whole system is managed by an electrical panel with PLC and operator panel with touch screen, where the recipes dedicated to each product are stored. According to the recipe, all the speed and flow parameters are automatically and individually adjusted for each turbine. Furthermore, each of the two modules can be operated or switched off.

As per tradition, all the heavy duty characteristics of Pangborn shot blasting systems have been maintained, with the internal lining of the shot blasting chamber, as well as other components subject to wear, made of special anti-wear P41 cast iron produced in its own foundry.

Pangborn plants can work in severe conditions over three shifts, while minimizing maintenance interventions.

The shot blasting machine installed by Marcegaglia has been in operation for more than a year and fully satisfies every need for the descaling process.

Ing Ceresetti states: "The quality of the supply in line with the highest market standards and the possibility of customization have allowed to meet and maintain the high performance demanded".

Pangborn Germany

V+S Vogel & Schemmann Maschinen GmbH

Schwerter Strasse 200, 58099 Hagen, Germany

Contact person is Philipp Söhnlein

Tel.: +49 2331 965-474

philipp.soehnlein@pangborn.com